Actualités

Filter Monitoring Enables Preventive Maintenance

Sustainable Progress in Powder Conveying: Supporting Resource Efficiency and Reduced Energy Use

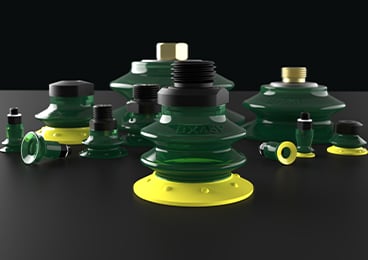

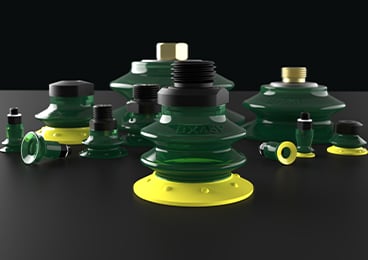

Nouvelles tailles pour les ventouses d’ouverture de sacs Piab

Piab a le plaisir d’annoncer l’expansion de sa célèbre gamme de ventouses d’ouverture de sacs avec l’introduction de deux nouvelles tailles : 18 mm et 42 mm...

Présentation des nouvelles tailles de la gamme BXP

Nos célèbres ventouses BXP, conçues pour la manipulation de surfaces poreuses ou non poreuses, sont désormais disponibles en tailles 6 mm et 8 mm.

Piab présente la piCLASSIC™ Neo

Piab est fière de dévoiler la piCLASSIC™ Neo, la dernière évolution de sa pompe à vide piCLASSIC™ largement reconnue. Conçues pour répondre à l’évolution des exigences des industries modernes, les variantes piCLASSIC™ Neo allient efficacité, adaptabilité et durabilité, établissant ainsi une nouvelle référence dans la technologie du vide.

Présentation de la compatibilité PolyScope X : améliorer les robots UR grâce aux solutions Piab

La compatibilité PolyScope X marque une avancée significative dans les capacités d’ Universal Robots (UR)...

Le piCOBOT® Electric est désormais disponible avec une intégration transparente au FANUC CRX

Le piCOBOT® Electric, entièrement électrique et fin, continue de redéfinir les applications de cobots en éliminant le tuyau d’air et le câblage.

Les piCOBOT® et piCOBOT®L sont désormais disponibles avec une configuration prête à l’emploi pour les ABB GoFa

Nous proposons désormais les piCOBOT® et piCOBOT®L avec des versions plug-in entièrement adaptées aux ABB GoFa, offrant ainsi une véritable fonctionnalité prête à l’emploi (Plug & Play).

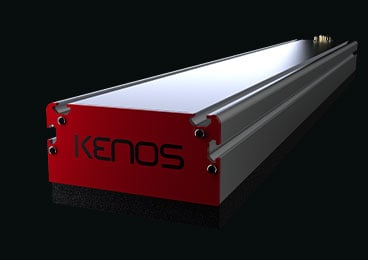

Conçue pour le succès : Découvrez la nouvelle série KVG E

La nouvelle série KVG E incarne l’engagement de Kenos® à fournir des solutions de pointe adaptées à divers besoins industriels.

L’ outil de palettisation pour cobots CPT est désormais configurable

Après deux années réussies en tant que produit de ligne sur mesure, l'outil de palettisation pour cobots CPT est maintenant prêt à passer à la gamme standard.

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

piCOMPACT®23 SMART désormais disponible avec IO-link Classe B

Piab étend le programme piCOMPACT23 SMART avec IO-link Classe B, équipé de domaines d’alimentation séparés entre l’alimentation de l’actionneur et l’alimentation du capteur.

Höganäs et Piab établissent un partenariat pour rendre la fabrication additive plus durable et efficace

Höganäs et Piab ont établi un partenariat pour tirer parti de leurs domaines d’expertise respectifs dans le but de...

Piab révolutionne la configuration des systèmes de vide avec l'outil OVM Pro 3D

Piab a lancé son très attendu OVM Pro 3D, un outil en ligne de pointe conçu pour transformer la façon dont les systèmes de vide sont configurés, simulés et optimisés.

Les nouvelles ventouses BXP ESD protègent les batteries

BXP ESD est une nouvelle série de ventouses modulaires, développées pour protéger les composants sensibles des batteries, des piles à combustible et de l’électronique contre les décharges électrostatiques pendant la manipulation.

piSAFE® - désormais encore plus sûr

Alors que le piSAFE® est désormais amélioré, la priorité reste la sécurité, mais avec la polyvalence et la durabilité comme nouveaux compagnons.

Le piCOBOT® Electric élimine les obstacles du mouvement du bras du cobot

Entièrement électrique, conception fine et absence de tuyaux d’air et de câblage. Le piCOBOT® Electric est une nouvelle réussite du programme piCOBOT® de Piab.

Nouvelle ventouse BXP de 45 mm, accompagnée des versions de 65 et 90 mm

Notre récente ventouse de 45 mm pour le segment BXP est désormais accompagnée des versions de 65 et 90 mm.

Nouvelle configuration prête à l’emploi du piCOBOT® pour les cobots FANUC CRX

Nous proposons désormais le piCOBOT® et le piCOBOT®L en versions entièrement adaptées au FANUC CRX. Prêt à l’emploi dans tous les aspects.

Les célèbres ventouses BXP accueillent leur nouveau membre et un configurateur

Nos ventouses BXP largement reconnues et le plus souvent utilisées pour prélever des objets à surfaces particulièrement poreuses, sont désormais complétées par une version de 45 mm.

Piab renforce son offre de préhension dans le secteur de la palettisation avec le LBG-50

Piab renforce sa présence sur le marché des solutions de palettisation avec un préhenseur de sacs léger préconçu, le LBG-50.