Neuheiten

Filterüberwachung für eine gezielte Wartung

Nachhaltiger Fortschritt in der Vakuumfördertechnik: Ressourceneffizienz durch intelligente Filterüberwachung

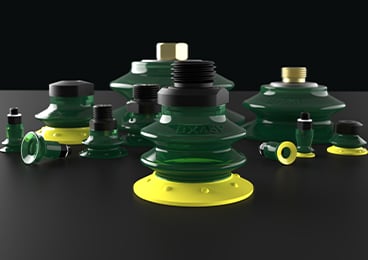

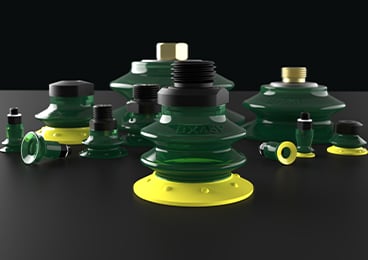

Neue Größen für die Saugnäpfe zum Öffnen von Beuteln von Piab.

Piab freut sich, mit der Einführung von zwei neuen Größen die Erweiterung seines gefeierten Sortiments an Saugnäpfen zum Öffnen von Beuteln bekannt geben zu können: 18 mm und 42 mm …

Die BXP-Familie wird um neue Größen erweitert.

Unsere hochgelobten BXP-Saugnäpfe, die für die Bearbeitung poröser oder nicht poröser Oberflächen entwickelt wurden, gibt es jetzt auch in den Größen 6 mm und 8 mm …

Piab stellt die piCLASSIC™ Neo vor

Piab präsentiert stolz die piCLASSIC™ Neo, die neueste Entwicklung seines weithin anerkannten piCLASSIC™ Vakuumejektors. Entwickelt, um den sich wandelnden Anforderungen moderner Industrien gerecht zu werden, vereinen die piCLASSIC™ Neo-Varianten Effizienz, Anpassungsfähigkeit und Nachhaltigkeit und setzen damit einen neuen Maßstab in der Vakuumtechnik.

Vorstellung der Polyscope X-Kompatibilität: Verbesserung von UR-Robotern mit Piab-Lösungen

Die Polyscope X-Kompatibilität stellt einen bedeutenden Fortschritt in den Fähigkeiten von Universal Robots (UR)...

piCOBOT® Electric jetzt mit nahtloser Integration an FANUC CRX erhältlich

Der vollelektrische, schlank konstruierte piCOBOT® Electric definiert Cobot-Anwendungen durch den Wegfall von Luftschläuchen und Kabeln neu.

piCOBOT® und piCOBOT®L jetzt mit Plug-and-Play-Konfiguration für ABB GoFa erhältlich

Wir bieten jetzt piCOBOT® und piCOBOT®L mit vollständig an ABB GoFa angepassten Plug-in-Versionen an, die echte Plug-and-Play-Funktionalität bieten.

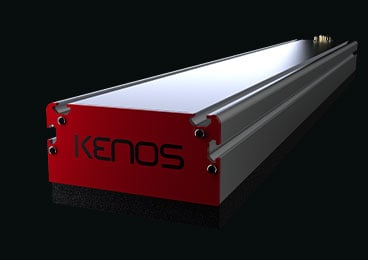

Auf Erfolg zugeschnitten: Lernen Sie die neue KVG E-Serie kennen

Die neu entwickelte KVG E-Serie verkörpert das Engagement von Kenos®, innovative Lösungen zu liefern, die auf die unterschiedlichen industriellen Anforderungen zugeschnitten sind.

Das kundenspezifische CPT ist jetzt ein konfigurierbares Produkt

Nach zwei erfolgreichen Jahren als kundenspezifisches Produkt wird das Cobot Palletizing Tool (CPT) nun in das Standard-Sortiment aufgenommen.

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

piCOMPACT®23 SMART jetzt mit IO-Link Klasse B erhältlich

Piab erweitert das piCOMPACT23 SMART-Programm um IO-Link Klasse B mit getrennten Leistungsbereichen zwischen Aktor- und Sensorstromversorgung.

Piab revolutioniert die Konfiguration von Vakuumsystemen mit dem OVM Pro 3D Tool

Piab hat das OVM Pro 3D vorgestellt, ein Online-Tool zur Konfiguration, Simulation und Optimierung von Vakuumsystemen.

Batteriehandhabung mit den neuen BXP ESD Saugnäpfen - Immer auf der sicheren Seite

BXP ESD ist eine neue Serie modularer Saugnäpfe, die entwickelt wurde, um empfindliche Komponenten in Batterien, Brennstoffzellen und Elektronik vor elektrostatischer Entladungen während der Handhabung zu schützen.

piSAFE® – jetzt noch sicherer

Mit der Weiterentwicklung von piSAFE® bleibt der Fokus auf Sicherheit erhalten, jedoch mit Vielseitigkeit und Nachhaltigkeit als neuen Begleitern.

piCOBOT® Electric durchbricht die Grenzen der Cobot-Armbewegung

Vollelektrisch, schlankes Design und ohne Luftschläuche und Verkabelung. Der neue piCOBOT® Electric steuert auf einen weiteren Erfolg des piCOBOT®-Programms von Piab zu.

Neuer BXP Saugnapf mit 45 mm Durchmesser, ergänzt durch die Versionen von 65 und 90 mm

Unser kürzlich vorgestellter Saugnapf mit 45 mm Durchmesser für das BXP-Segment wird nun durch Versionen mit 65 und 90 mm Durchmesser ergänzt.

Neue piCOBOT®-Plug-and-Play-Konfiguration für FANUC CRX-Cobots

Wir bieten jetzt piCOBOT® und piCOBOT®L in vollständig an FANUC CRX angepassten Versionen an. Plug-and-Play in jeder Hinsicht.

Die beliebten BXP-Saugnäpfe werden um ein neues Mitglied aus der Produktfamilie erweitert und sind nun konfigurierbar

Unsere weithin gelobten BXP-Saugnäpfe, häufig genutzt zur Kommissionierung von Objekten mit besonders poröser Oberfläche, werden nun durch eine 45-mm-Version ergänzt.

Piab stärkt seine Position bei der Palettierung mit dem LBG-50

Piab stärkt seine Position auf dem Markt für Palettierlösungen mit dem vorgefertigten leichten Sackgreifer LBG-50.