진공 기술을 이용환 세련된 자동화

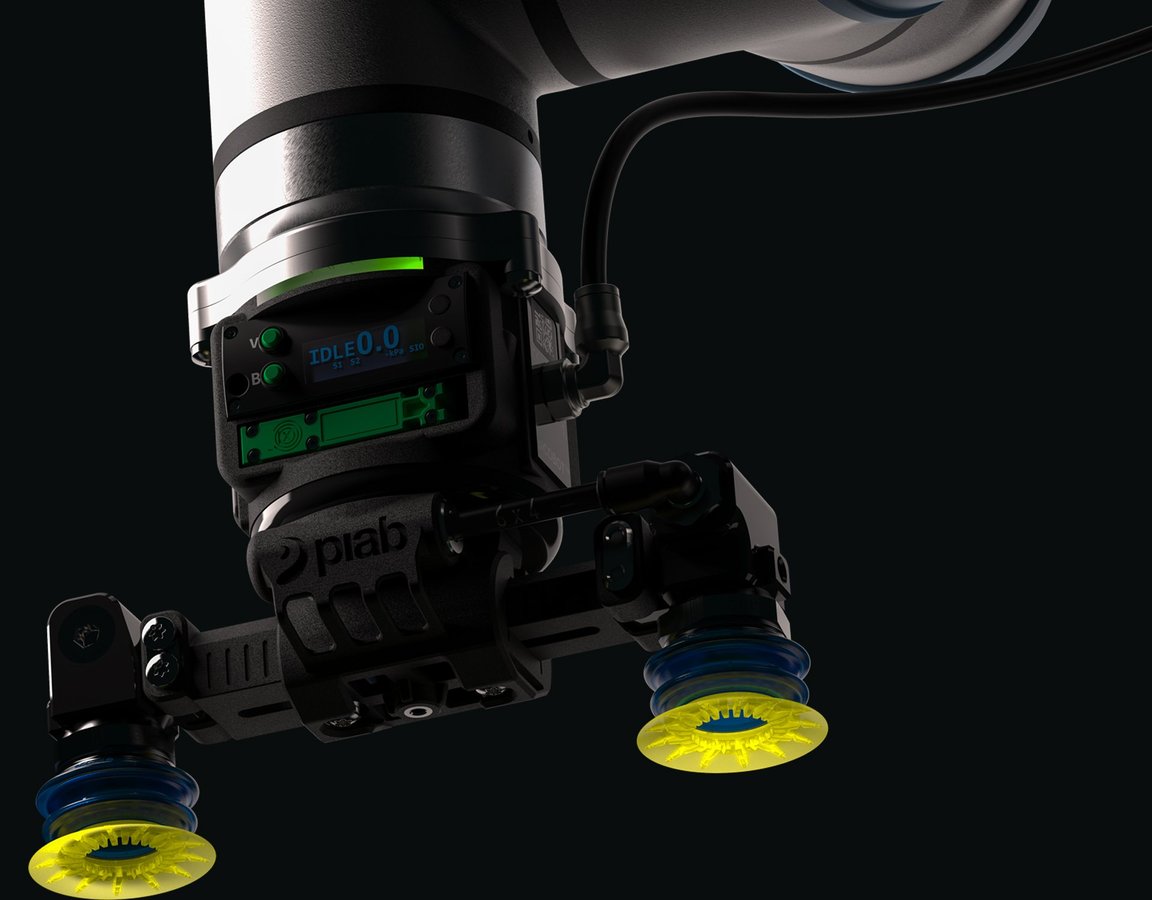

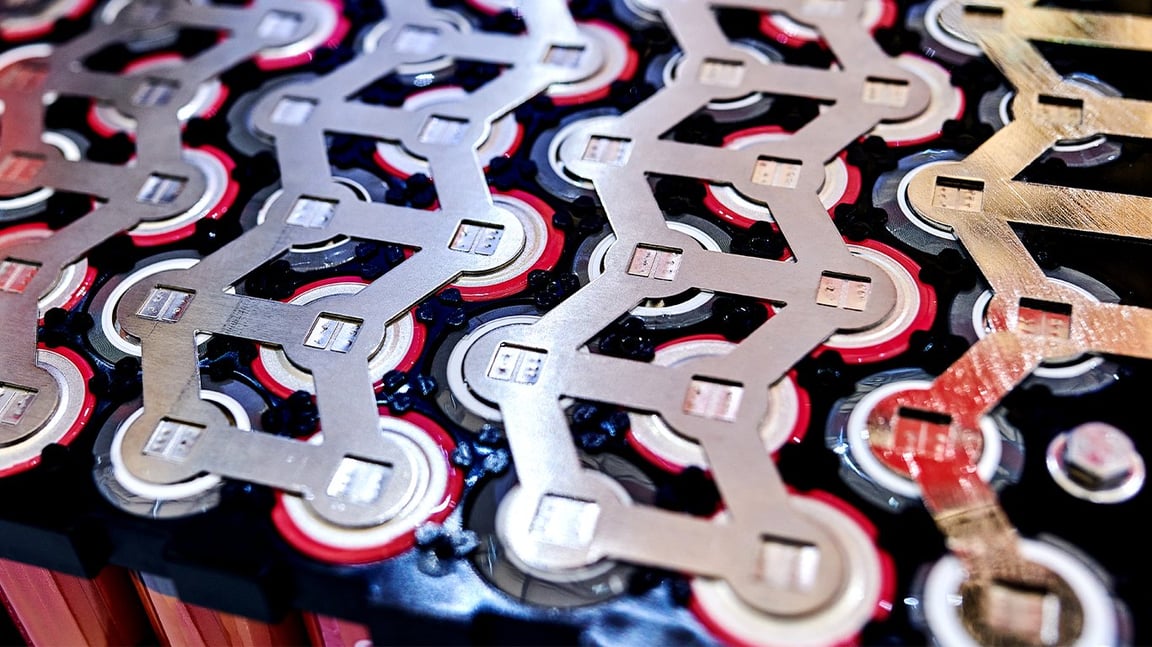

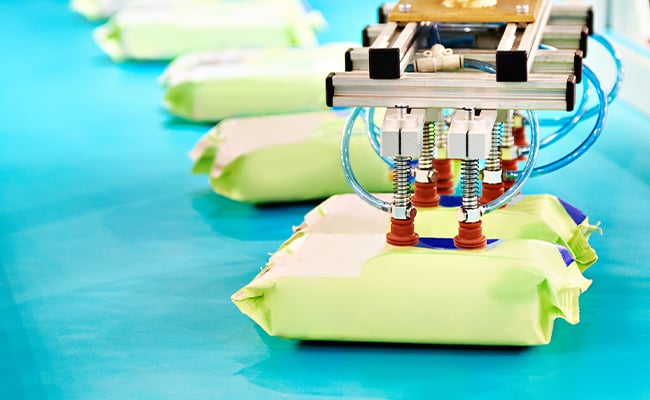

Piab의 진공 구동식 핸들링 시a스템과 로봇 도구는 전 세계 모든 산업 부문에서 활용되고 있습니다. 당사의 맞춤형 솔루션은 생산 공정의 크기, 무게, 모양 또는 순위에 관계없이 원자재 처리부터 단일 물체의 조립, 분류 및 포장에 이르기까지 애플리케이션을 지원합니다.

Piab의 진공 구동 솔루션은 생산성 향상, 일관된 성능 및 유지되는 품질 표준을 위해 수작업을 크게 줄여줍니다.

진공 구동 시스템은 유해한 작업 작업을 줄이고 분말 및 곡물부터 상당한 크기와 무게의 단일 물체에 이르기까지 산업 구성 요소를 안전하게 처리할 수 있게 해줍니다.

기술과 설계로 인해 Piab 진공 시스템은 긴 서비스 수명, 최소한의 유지 관리 및 낮은 에너지 소비를 보장하여 환경에 미치는 영향을 줄입니다.

산업분야 선택

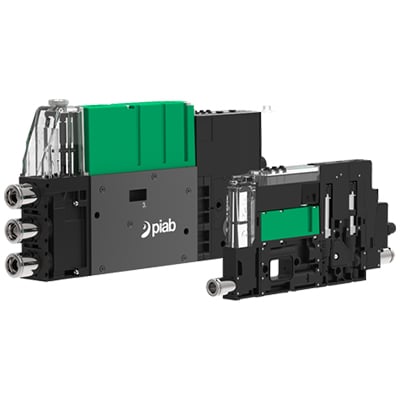

COAX® - 우수한 진공 이젝터

세계적으로 인정받는 COAX® 이젝터를 기반으로 한 시스템은 기존 진공 시스템보다 3배 더 많은 진공흡입유량을 제공하여 사이클 속도를 높이고 에너지 소비를 줄입니다. 파이아브(Piab)가 발명했다

진공 자동화 부서

Piab 진공 자동화 사업부는 모든 산업 분야에서 생산성, 안전 및 효율성 향상을 위한 진공 기술 및 로봇 도구 분야의 글로벌 리더입니다. 표준화된 제품과 맞춤형 솔루션을 결합하여 에너지 소비와 재료 낭비를 최소화하면서 안전한 작업 환경을 구현합니다.

검색

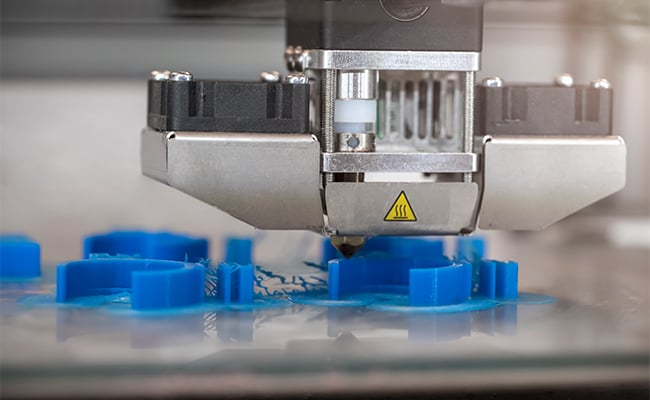

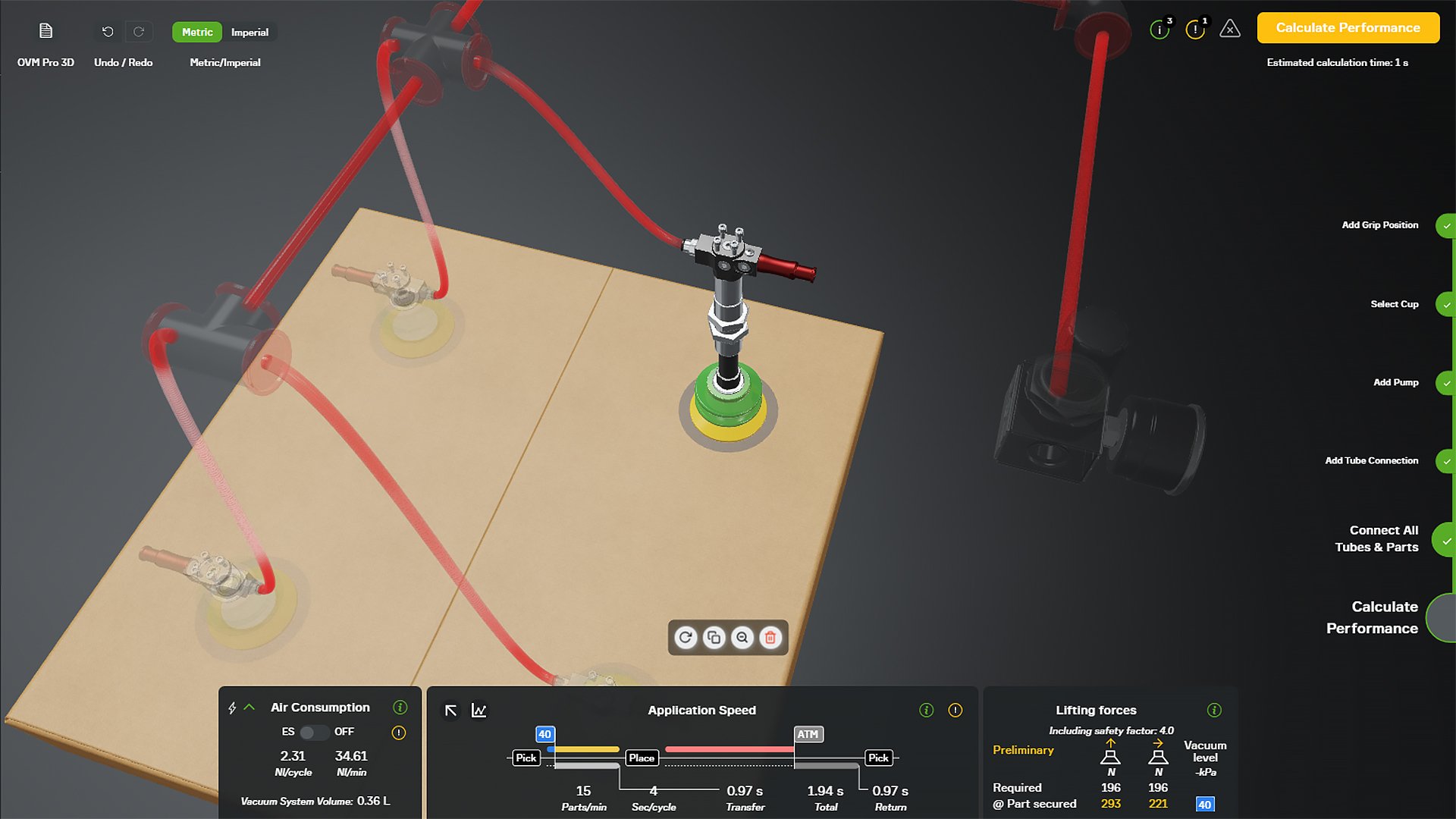

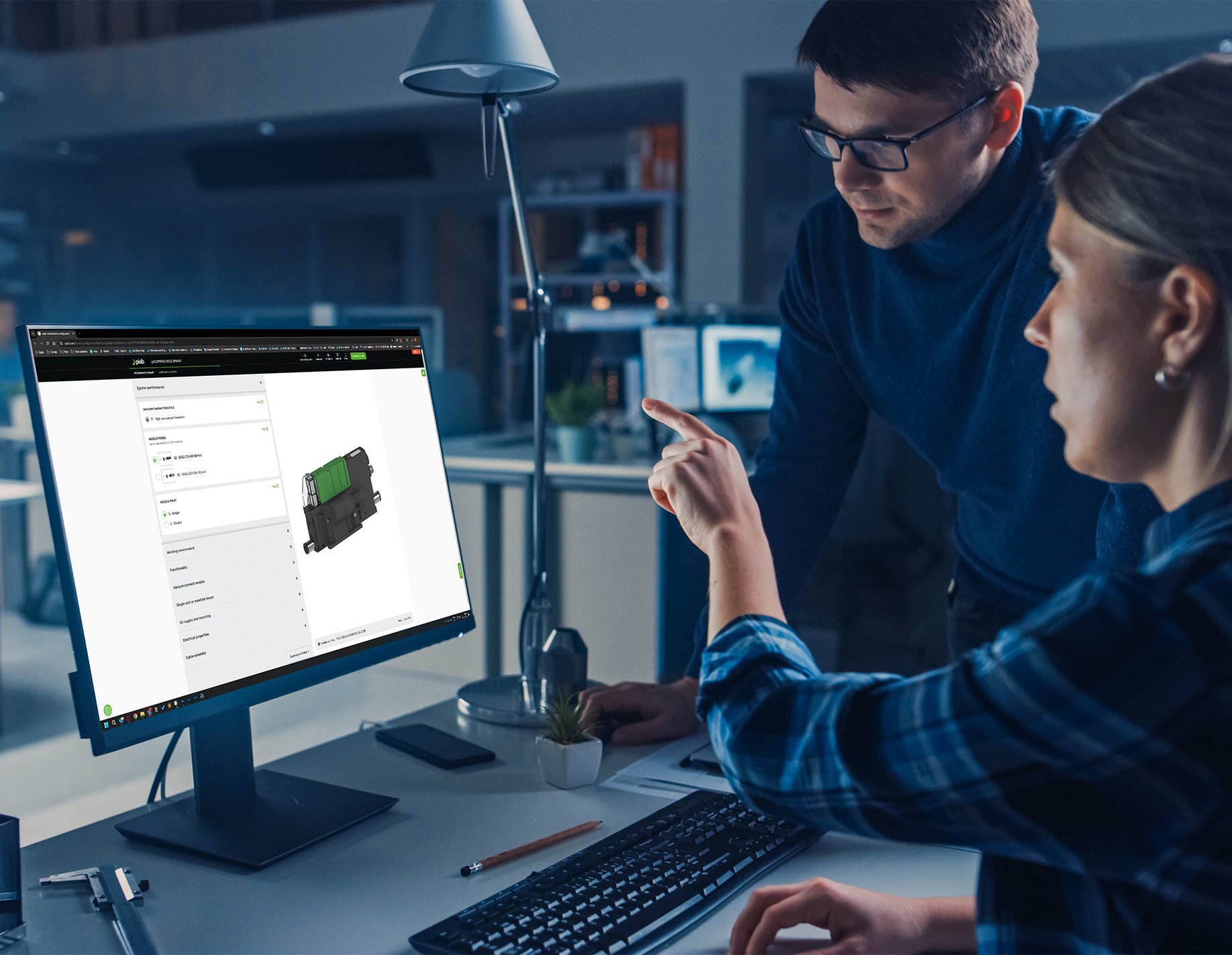

자체 진공 시스템 설계

OVM Pro 3D는 자체 진공 시스템을 물리적으로 구현하기 훨씬 이전에 가상 환경에서 설계, 테스트, 개선할 수 있는 기능을 제공합니다. 로그인하여 Piab의 광범위한 진공이젝터 펌프, 진공패드, 그리퍼, 피팅 및 액세서리로 고유한 애플리케이션을 만드십시오.

OVM Pro 3D로

제품 구성하기

Piab의 제품 구성 도구는 모든 고객에게 효과적인 도구입니다. 유익한 텍스트, 이미지 및 기능을 통해 지원되는 안내 경험을 통해 제품 선택 프로세스를 간소화하도록 설계되었습니다. 제품 검색 및 맞춤화에서 견적 또는 주문으로 원활하게 전환됩니다.

제품구성

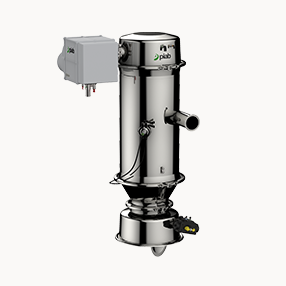

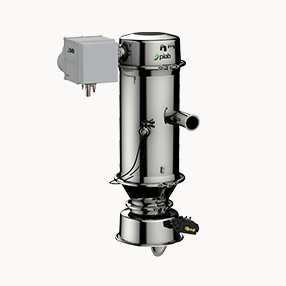

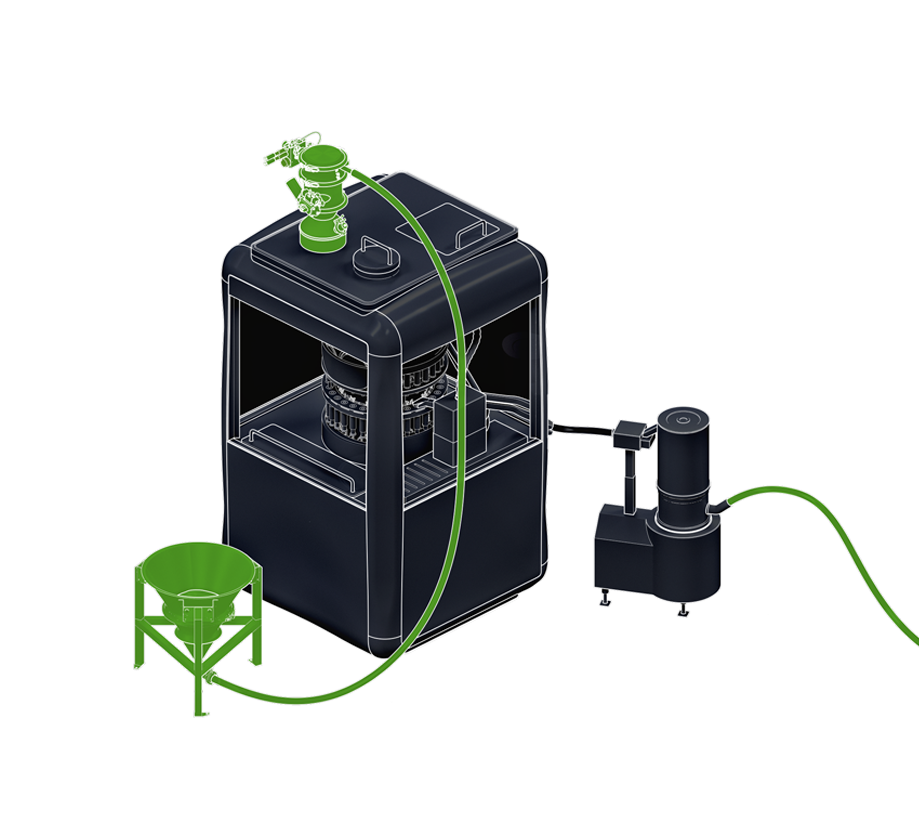

진공 이송의 장점

진공 이송이 분말, 과립, 소형 부품을 이동하는 방법을 알아보세요. 이러한 솔루션이 스크류 컨베이어(오거), 버킷 엘리베이터, 벨트 컨베이어와 같은 기계적 이송 옵션과는 어떻게 다른지 비교해보세요.

자세히 알아보기최신 뉴스

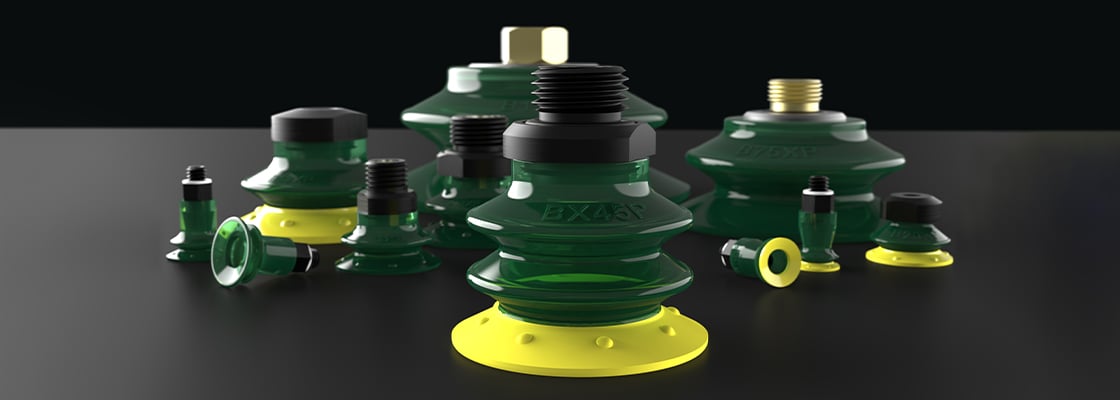

BXP 제품군에 새 크기 도입: 6mm 및 8mm

범위 확장: 새로운 크기의 Piab 비닐팩 개봉 진공패드

Piab, 현대적이고 지속 가능한 진공 기술의 다음 단계인 piCLASSIC™ Neo 출시

서명

무료 계정 신청

- CAD 파일

- 납기

- 데이터 시트

- 견적 요청

- 매뉴얼

- 견적 요청

- 자료 문서