News

Enabling a continuous, climate‑smart dry powder process at cReal

How cReal’s Bjuv plant uses Piab’s closed vacuum conveyors to run a continuous, climate-smart oat powder process that can replace traditional milk powder in food production.

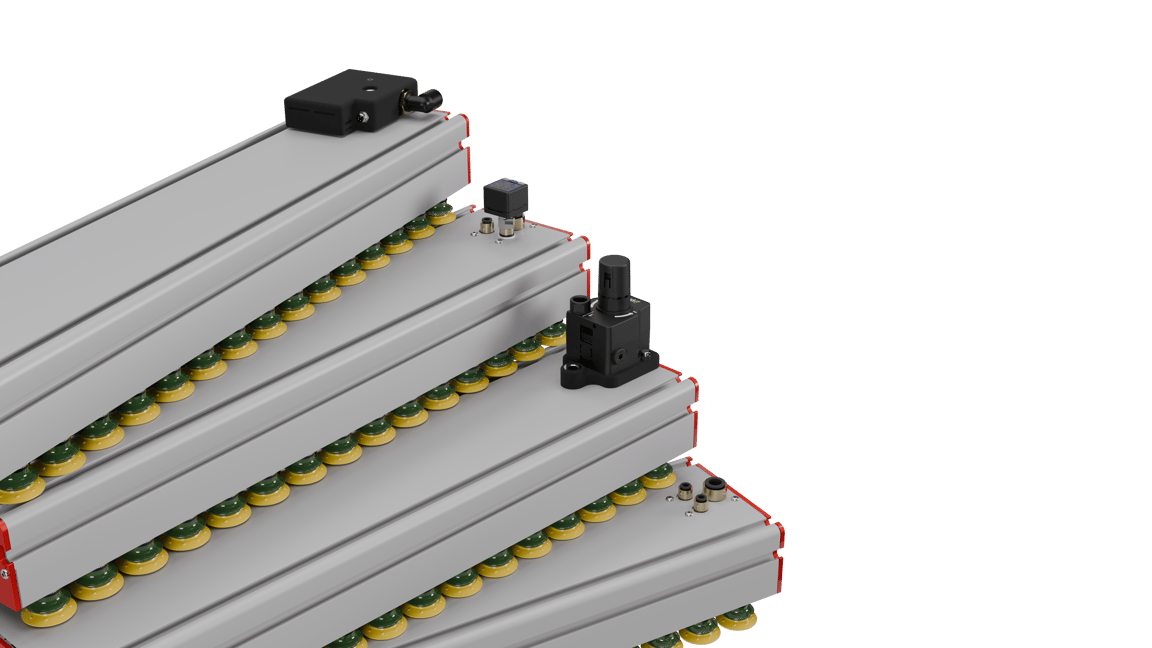

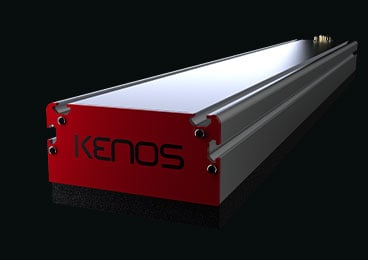

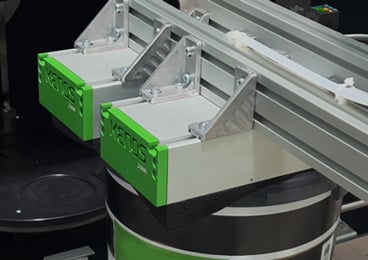

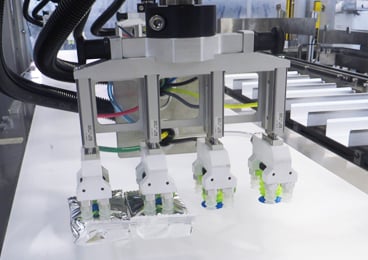

Kenos® expands vacuum grippers KVG150 E-series

Kenos® proudly announces the expansion of its KVG150 E-series, now offering the extensive KVG150C, equipped with cups, alongside its trusted foam version, the KVG150F.

Piab Group’s European Supply Unit Relocates to Modern Facility in Butzbach

After 13 years in the current location, Piab Group’s European Supply Unit (ESU) is relocating to a brand-new, state-of-the-art facility in Butzbach, Germany.

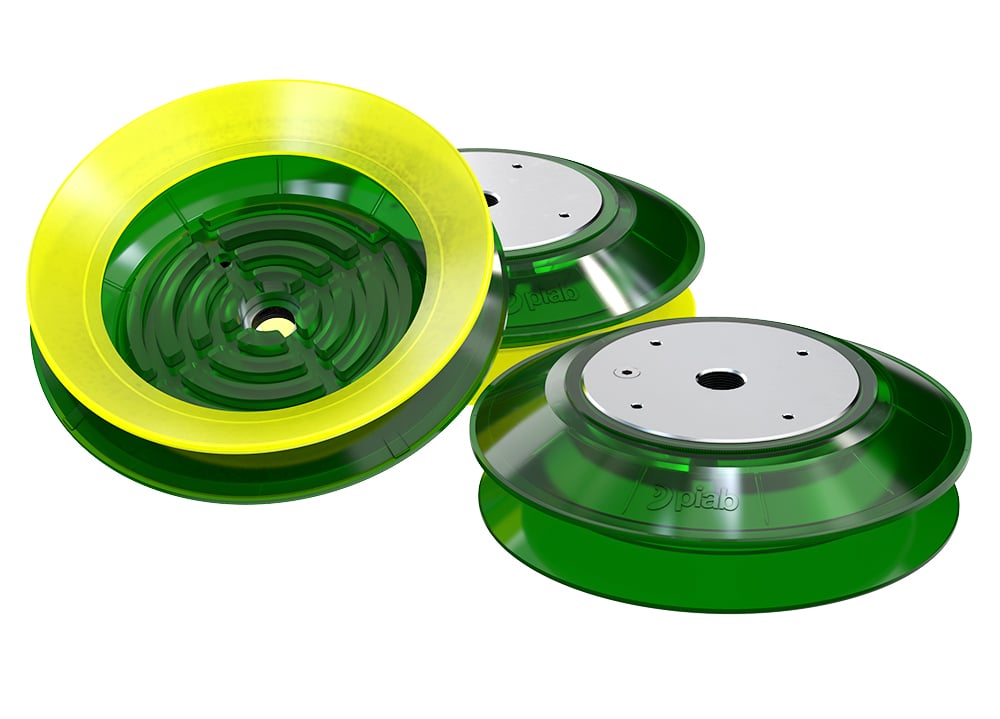

Introducing New Sizes to the BGX Family

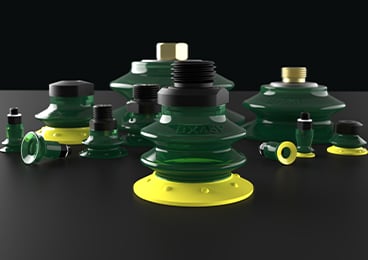

We announce the expansion of our BGX Cups family with the addition of two new sizes: 27mm and 63mm...

PFAS-free Operations: Raising the Bar for Sustainable Food Manufacturing

Piab launches PFAS-free filters and investigates all products for PFAS, reinforcing its commitment to sustainability, safety, and regulatory compliance.

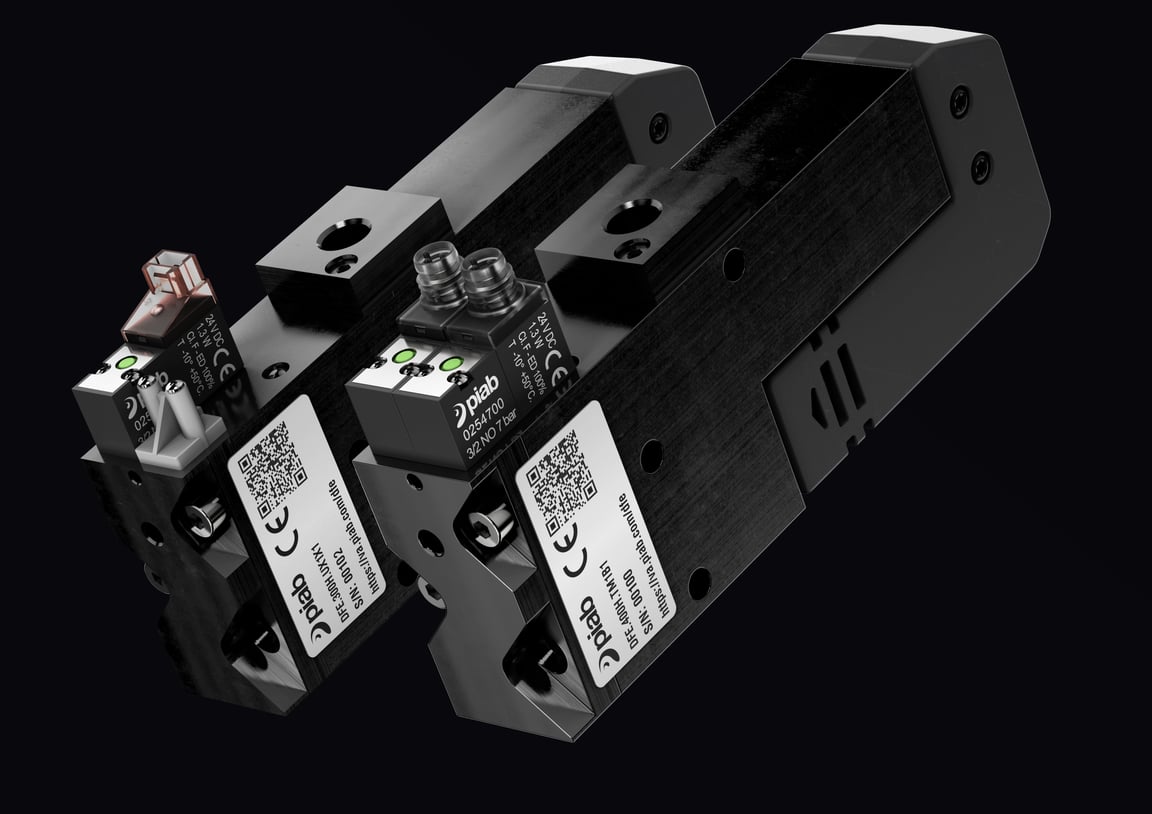

Introducing the DFE Vacuum Pump: Elevating Industrial Efficiency

Piab is proud to introduce the DFE (Dual Function Ejector), a compact and stackable vacuum pump engineered for durability and versatility.

Piab exhibiting at EV Hybrid Vehicle Battery Show

Piab exhibiting at EV Hybrid Vehicle Battery Show

Blue Detectable Sealings for Advanced Food Safety

Boost food safety with Piab’s new blue detectable sealings for piFLOW®f: easy-to-spot and magnetically detectable, they help prevent contamination and simplify compliance in food manufacturing.

Filter Monitoring Enables Preventive Maintenance

Sustainable Progress in Powder Conveying: Supporting Resource Efficiency and Reduced Energy Use

New Sizes for Piab's Bag Opening Cups

Piab is excited to announce the expansion of its acclaimed Bag Opening Cups lineup with the introduction of two new sizes: 18mm and 42mm...

Introducing New Sizes to the BXP Family

Our acclaimed BXP cups, designed for handling porous as well as nonporous surfaces, now include 6mm and 8mm sizes...

Piab Introduces piCLASSIC™ Neo

Piab proudly unveils piCLASSIC™ Neo, the latest evolution of its widely recognized piCLASSIC™ vacuum pump. Designed to meet the evolving demands of modern industries.

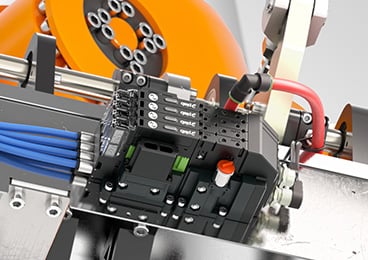

Introducing Polyscope X Compatibility: Enhancing UR Robots with Piab Solutions

Polyscope X compatibility marks a significant advancement in the capabilities of Universal Robots (UR), enabling a seamless transition to more efficient and flexible automation solutions.

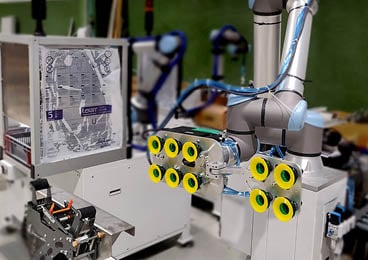

piCOBOT® Electric now available with seamless integration to FANUC CRX

The fully electric, slim-designed piCOBOT® Electric continues to redefine cobot applications by eliminating air tubing and cabling.

piCOBOT® and piCOBOT®L Now available with plug & play configuration for ABB GoFa

We now offer piCOBOT® and piCOBOT®L with fully ABB GoFa-adapted plug-in versions, delivering true Plug & Play functionality.

Tailored for success: Meet the new KVG E-Series

The newly developed KVG E-Series embodies Kenos®’ commitment to delivering cutting-edge solutions tailored to diverse industrial needs.

Piab and Kenos tools enable safe street lighting manufacture

Italian system integrator MVQuadro used Kenos® FlexiGrip KFG grippers and an array of suction cups from Piab to successfully assist a manufacturer of street lights.

Custom tool CPT now a configurable product

After two successful years as a custom line product, cobot palletizing tool CPT is now due for a move to the standard assortment.

European multinational doubles tomato sauce production with Piab-Kenos setup

Successful partnering between Piab and CFT Group, Italy, produced a vacuum-driven, tailormade solution that doubled the productivity in a tomato sauce line.

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

Kenos KVG grippers to improve productivity in metal sheet handling

By using Piab's Kenos® KVG grippers, Automation Technology designed and built a folding, joining, assembly, and riveting line for galvanized sheets, optimizing not only cycle times but also operator safety.

piCOMPACT®23 SMART now available with IO-link Class B

Piab extends the piCOMPACT23 SMART program with IO-link Class B equipped with separate power domains between actuator power and the sensor power.

Industry 4.0 ready? Don’t forget about your manual sub-flows

Industry 4.0 has been on the agenda for quite some time now, but its realization is a far away from what fills our daily news feeds.

Piab revolutionizes vacuum system configuration with OVM Pro 3D tool

Piab has launched its highly anticipated OVM Pro 3D, a cutting-edge on-line tool designed to transform the way vacuum systems are configured, simulated and optimized.

New BXP ESD cups move batteries to safer ground

BXP ESD is a new series of modular suction cups, developed to protect sensitive components in batteries, fuel cells and electronics from electrostatic discharge during handling.

piSAFE® - now even safer

As piSAFE® is now upgraded the safety focus remains, however with versatility and sustainability as new companions.

piCOBOT® Electric breaks the barriers of cobot arm movement

Fully electric, slim design and absence of air-tubing and cabling. The new piCOBOT® Electric heads towards another success for Piab's piCOBOT® program.

Piab Locations on the Move

New BXP 45mm suction cup accompanied by 65 and 90 mm versions

Our recent 45 mm cup for the BXP segment is now accompanied by 65 and 90 mm versions.

New piCOBOT® plug & play configuration for FANUC CRX cobots

We now offer piCOBOT® and piCOBOT®L in completely FANUC CRX adapted versions. Plug & Play in every aspect.

![Piab's widely acclaimed BXP cups, most often used to pick objects with particularly porous surfaces, will now be complemented with a 45 mm [1.77 in] version.](https://www.piab.com/cdn-cgi/image/width=1152,format=auto/contentassets/9d3be9aeaf0544828765c0d4620db648/acclaimed-bxp-cups-see-new-family-member-listing-360px.jpg?ref=DE8C45C4BA)

Acclaimed BXP cups see new family member and configurator premiere

Our widely acclaimed BXP cups, most often used to pick objects with particularly porous surfaces, will now be complemented with a 45 mm [1.77 in] version.

Piab strengthens its grip on palletizing with the LBG-50

Piab strengthens its grip on the palletizing solutions market with a pre-engineered lightweight bag gripper, the LBG-50.

Safe palletizing of wet vehicle batteries with Piab DURAFLEX® Friction Cups

Piab's DURAFLEX® Friction Cups, plays a major part in Gruppo Esea's pick-and-place system for a leading automotive battery manufacturer.

Kenos® foam grippers to support high-speed handling of paint drums

Using Kenos® KVG120 foam grippers by Piab, Dromont Group designed a successful pick-and-place system for a paint production line at a major UK chemical company.

From Ground to 65 feet up: Piab’s Automated System Conveys Corn Seed Coating Powder up to Fourth Floor

Bayer Hungaria Kft. enjoys the benefits of Piab’s automated solution for their corn seed coating powder transportation. The implementation of Piab's piFLOW®f conveyors completely reduced the need for manual handling.

Piab carton palletizing solution improved Steelgran’s productivity by 35%

Piab vacuum foam gripper Kenos® KVGL has improved the operating cycle of end-of-line robots by 35% for Spanish company Steelgran Componentes S.A.

Four decades and still running – a story of conveyors that last

To celebrate the 70-year anniversary of Piab, the Vacuum Conveying Division launched a competition to find the oldest, still running Piab vacuum conveyor out there. And it was found...

Increasing palletizing cycles in a food application.

MAXPRO achieved great advantages in bag handling with Piab's Kenos® KVGL gripper...

Piab Group acquires COVAL

Piab Group has acquired COVAL, a major global player in vacuum automation components and systems...

Four useful additions to Piab’s Automotive suction cups

Four new suction cups extend the PAF (Piab Automotive Flat) and PAB (Piab Automotive Bellow) families with two new sizes each - Ø100mm and Ø125mm.

Increased productivity in the packaging and palletizing of boxes.

Using Piab's KVG and KVGL series of Kenos® grippers, Eklego designed and manufactured a state-of-the-art end-of-line system...

Piab piGRIP® Foam Lip - FLIW handles objects with irregular or unstructured surfaces

FLIW (Foam Lip Wide) is our latest contribution to the piGRIP® series. Fully configurable with a multitude of combinations, makes it a perfect fit for any picking application...

Piab’s new egg suction cup ECX36 increases productivity of egg handling processes

A stable though gentle suction cup for egg handling processes enabling high speed applications. Test them now!

A gentle grip on any fruit from avocado to zucchini with Piab’s new fruit suction cup FCX50

The FCX50 suction cup picks any fruit independently of shape or texture even off-axis thanks to its multiple lips and flexible bellows...

Selected Joulin grippers now sold under the Kenos® brand

Piab has integrated three of Joulin's gripper ranges into its Kenos® portfolio, while the solutions for the heavy-duty industries continue to be marketed under the Joulin brand...

Introducing piCOMPACT®10X SMART, Piab adds functionality to a small footprint ejector

A compact, efficient, and intelligent ejector that enables you to take the next step in...

Palletizing in rugged and dusty environments made easy with the new Kenos®Safe&Light

With a payload of up to 130 pounds, depending on the selected gripper size, the KSL is ideal for cardboard handling in warehouse and e-commerce applications...

Mini but mighty – the new Kenos®MiniGrip offers a stable and rigid hold even on rough surfaces

The Kenos®KMG is a vacuum foam gripper that can be adapted to tight clearance applications in an EOAT similar to a suction cup...

Adapt the new versatile Kenos®FlexiGrip to perfectly match your application requirements

The new Kenos®KFG vacuum foam gripper offers many advantages in mass production of products with uneven, rough, structured or textured surfaces...

Piab’s #1 item picker family is now extended with the smaller cup size of 25 mm and additional features

Discover Piab’s #1 item picker: MX multi-purpose suction cups offer extreme gripping capabilities on any surface from bag to box – ideal for e-commerce...

Automatic box palletizing in the food industry

BX suction cups made of double-strength Duraflex® in combination with Piab's COAX® vacuum generation technology have enabled Tradicional Panadera to palletize different carton formats with a single gripper.

Lifting more with less with Piab’s new piCOBOT®L vacuum pump unit

With its lifting capability of up to 35 lbs, the piCOBOT®L is particularly attractive for...

The complex road to simplicity

Our R&D department has been working with solutions for Industry 4.0. since 2017; I joined the team in 2020. It might sound controversial, but...

Improve automation acceptance by conveying bulk solids with Piab’s new product series

Vacuum conveying solutions for powders, granules, and small particles must be easy to adapt, efficient, and sustainable. Piab continues to evolve manufacturing workplaces with...

Flexible and efficient handling of raw wood runners in a strapping system

Using Piab's Kenos® KVG grippers, Officina Meccanica Sestese SpA designed and manufactured an end-of-line packaging machine installed at a leading company in Southeast Europe, a manufacturer of components for the furniture industry.

Coffee delight thanks to Piab's vacuum conveyor at Minges Coffee Roasters

The coffee capsules and pods from Minges Coffee Roasters have been filled easily thanks to Piab's piFLOW®f...

Increased productivity in forming boxes in a veterinary application

Using Piab's B52XP suction cups and piCOMPACT23 SMART pump, Cob-Solution designed and built a system to handle the picking and opening of cardboard boxes at Rao Farmaceutici, Sicilian veterinary pharmacy that is investing in e-commerce and selling throughout all Europe.

The dream team: The Wyzo sidebot combined with Piab's extremely lightweight Mini Cobot gripper (MCG)

With a maximum payload of 2.2 pounds for the Wyzo sidebot, the weight of the gripper is critical. Therefore Piab's featherweight Mini Cobot gripper (MCG) at 9.5 oz, fits perfectly.

The Mini Cobot Gripper (MCG) from Piab – small is powerful!

Weighing just 9.5 ounces, the MCG is probably the lightest cobot gripper in the world. It lifts parts up to...

Piab’s new Cobot Palletizing Tool (CPT) helps to get more pallets out per day

The CPT is a smart and compact cobot gripper. Its multi-zone gripper surface picks several boxes...

Piab extends its line of suction cup accessories

With three new attachment options Piab is offering further EOAT design possibilities for optimal handling system solutions construction...

Piab launches the P suction cups series with profiled rubber strips

Piab has developed a specific set of suction cups for rough textured surfaces...

Piab adds new sizes to its Bellows Polyurethane suction cup family: B150P and B200P

With their short bellows, these Bellow Polyurethane (BP) suction cups are ideally suited to handle objects of...

Flimsy bags can now be picked and handled more easily with a safe grip

Bags become more thinner and flimsier and need to be treated carefully. Thanks to the...

Reinventing intralogistics

A unique, intelligent, solution that automates the intralogistics and material handling from inbound to the finished, delivered kitted items at the individual production lines has been created...

Easy separation of samples with vacuum technology from Piab

Sample separation is a regular task in chemical laboratories to conduct further research. Piab’s Lab Vac vacuum pumps ensure...

Quick to market with new canned products thanks to efficient palletizing solutions from Piab

With Piab‘s Kenos® area gripper, the duration of the palletizing process of food and beverage cans is significantly...

Automatic handling of packaged biscuits with Piab’s vacuum technology

Using Piab's suction cups and vacuum pumps, Tecno Pack SpA has designed and built grippers...

Choosing the right cobot gripper for cosmetics handling

For the cosmetics industry, placing products into packages is a particular challenge. Today this task is often fulfilled by an armada of workers, but with...

The dm distribution center relies on Piab suction cups

dm is currently the largest drugstore in Europe. At their distribution center a large part of the pallets is depalletized with...

With piSOFTGRIP® 100-4, Piab is launching the largest gripper of this series

Piab is proud to introduce the new and largest soft gripper developed especially with food industry...

A partnership between Höganäs and Piab is set to make Additive Manufacturing more sustainable and efficient

Höganäs and Piab have formed a partnership to leverage their respective areas of expertise with the goal of advancing...

Elevating the learning experience

To better facilitate a high-performing learning environment for our customers and partners, we at Piab is now launching...