News

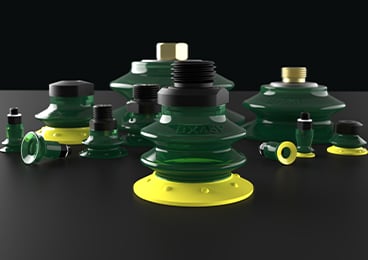

Piab 推出 piCLASSIC™ Neo

Piab 推出引以为豪的 piCLASSIC™ Neo,这是其广受好评的 piCLASSIC™ 真空发生器系列的最新产品。piCLASSIC™ Neo 系列旨在满足现代工业不断变化的需求,将效率、适应能力和可持续性相结合,为真空技术树立了新标杆。

推出 Polyscope X 兼容性:通过 Piab 解决方案增强 UR 机器人

Polyscope X 兼容性标志着 Universal Robots 能力的一次重大飞跃,使用户能够无缝过渡到更高效、更灵活的自动化解决方案。

piCOBOT® Electric 现在可与 FANUC CRX 无缝集成

全电动、纤薄设计的 piCOBOT® Electric 继续通过消除空气管线和布线重新定义协作机器人应用。

piCOBOT® 和 piCOBOT®L 现在提供适合 ABB GoFa 的即插即用配置

我们现在提供 piCOBOT® 和 piCOBOT®L,配备完全适应 ABB GoFa 的插件版本,提供真正的即插即用功能。

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

Solukon 在新粉末收集单元中应用了 Piab 的真空输送机(2)

piCOMPACT®23 SMART 现已配备 IO-link B 类选项

Piab 针对 IO-link B 类扩展了 piCOMPACT23 SMART 程序,并在执行器电源和传感器电源之间配备了独立的电源域。

Piab 排名第一的物料抓取吸盘系列现推出 25 mm 的小尺寸吸盘以及一些附加功能,得以更加完善

了解 Piab 排名第一的物料抓取吸盘:MX 多用途吸盘在从包袋到包装箱的任何表面上都具有极高的抓取能力,是电子商务的理想之选…

piCOBOT® Electric 打破了协作机器人手臂运动的障碍

全电动、超薄设计,无空气管和布线。全新的 piCOBOT® Electric 引领 Piab 的 piCOBOT® 计划再创辉煌。

适用于 FANUC CRX 协作机器人的全新 piCOBOT® 即插即用配置

我们现提供完全与 FANUC CRX 兼容的 piCOBOT® 和 piCOBOT®L 版本。全方位即插即用。

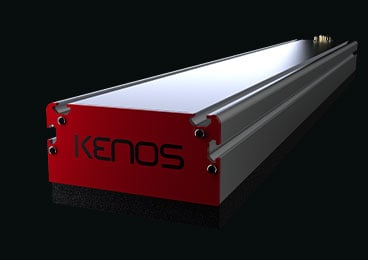

AVAC的一系列产品现在以Piab品牌销售

去年八月,Piab收购了AVAC Vakuum Teknik AB,这是一家在瑞典享有盛誉的真空专家,拥有一套完善的产品组合。现在,AVAC的一部分产品已经被纳入Piab的产品系列中。

四十余载,依然在路上 - 一段有关输送机的传奇还在延续

为庆祝 Piab 成立 70 周年,真空输送事业部发起了一场竞赛,以寻觅最古老、仍在役的 Piab 真空输送机。而这最终“花落”……