новости

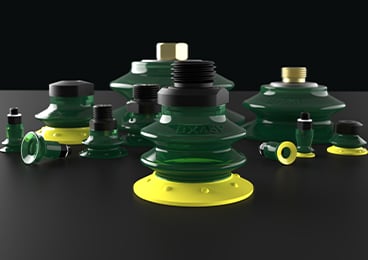

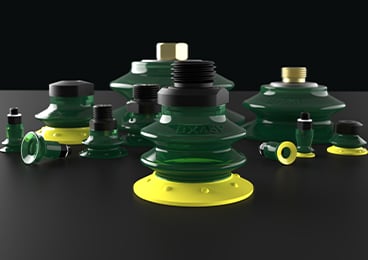

Новые размеры присосок Piab для вскрытия пакетов

Piab рад сообщить о расширении диапазона широко признанных присосок для вскрытия пакетов, представляя два новых размера: 18 мм и 42 мм…

Представляем новые размеры в семействе BXP

Наши завоевавшие признание присоски BXP, разработанные для работы как с пористыми, так и с герметичными поверхностями, сейчас включают в себя размеры 6 мм и 8 мм…

Piab представляет piCLASSIC™ Neo

Компания Piab с гордостью представляет piCLASSIC™ Neo, новейшую разработку широко известного вакуумного насоса piCLASSIC™. Разработанные с учетом меняющихся требований современных отраслей промышленности, варианты исполнения piCLASSIC™ Neo сочетают в себе эффективность, адаптивность и экологичность, устанавливая новую планку в вакуумной технологии.

Представляем совместимость с Polyscope X: Усовершенствование роботов UR с помощью решений Piab

Polyscope X compatibility marks a significant advancement in the capabilities of Universal Robots (UR), enabling a seamless transition to more efficient and flexible automation solutions.

piCOBOT® Electric теперь доступен с полной интеграцией с FANUC CRX

Полностью электрический, с тонким дизайном piCOBOT® Electric позволяет и далее переосмысливать применение коботов благодаря отсутствию пневматических трубок и кабелей.

piCOBOT® и piCOBOT®L Теперь доступны с возможностью динамической настройки конфигурации для ABB GoFa

Теперь мы предлагаем piCOBOT® и piCOBOT®L с полностью адаптированными к ABB GoFa версиями подключаемых модулей, обеспечивающими настоящую функциональность Plug & Play.

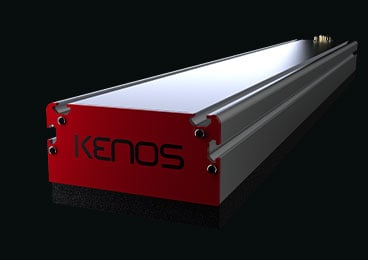

Обречено на успех: Встречайте новое устройство KVG серии «Е»

Недавно разработанное устройство KVG серии «Е» воплощает в себе стремление Kenos® поставлять передовые решения, отвечающие самым разнообразным промышленным потребностям.

Custom tool CPT now a configurable product

After two successful years as a custom line product, cobot palletizing tool CPT is now due for a move to the standard assortment.

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

Программа piCOMPACT®23 SMART теперь доступна с IO-link класса B

Компания Piab расширяет программу piCOMPACT23 SMART продуктом IO-link класса B, оснащенным отдельными доменами питания между питанием привода и питанием датчика.

Новые присоски BXP ESD переводят аккумуляторные батареи на более безопасный уровень

BXP ESD — это новая серия модульных чашечных присосок, разработанная для защиты чувствительных компонентов аккумуляторных батарей, топливных элементов и электроники от электростатического разряда во время работы с ними.

piSAFE® - now even safer

As piSAFE® is now upgraded the safety focus remains, however with versatility and sustainability as new companions.

piCOBOT® Electric разрушает барьеры движения манипулятора кобота

Полностью электрический, малогабаритная конструкция и отсутствие пневматических трубок и кабелей. Новый piCOBOT® Electric — это еще один успех программы piCOBOT® компании Piab.

Новая чашечная присоска BXP 45 мм сопровождается версиями 65 и 90 мм

К нашей недавней 45-миллиметровой присоске для сегмента BXP теперь добавились версии 65 и 90 мм.

Новая готовая конфигурация piCOBOT® для коботов FANUC CRX

Теперь мы предлагаем piCOBOT® и piCOBOT®L в версии, полностью адаптированной к FANUC CRX. Готовый к использованию во всех аспектах.

Семейство признанных присосок BXP принимает в свои ряды новое изделие и дополняет конфигуратор

Наши повсеместно признанные присоски BXP, которые чаще всего используются для подбора предметов с особенно пористой поверхностью, теперь будут дополнены 45-миллиметровой версией.

Четыре десятилетия и все еще работают – история конвейеров, которая не кончается

В честь 70-летнего юбилея компании Piab подразделение вакуумной транспортировки объявило конкурс на поиск самого старого, еще работающего вакуумного конвейера Piab. И он был найден...

Четыре полезных дополнения к автомобильным чашечным присоскам Piab

Четыре новые чашечные присоски расширяют семейства PAF (Piab Automotive Flat) и PAB (Piab Automotive Bellow) двумя новыми размерами: Ø100 мм и Ø125 мм.

Пенорезиновая присоска piGRIP® от PIAB — FLIW перемещает объекты с неровными или неструктурированными поверхностями

FLIW (пенорезиновая присоска широкая) — это наш последний вклад в серию piGRIP®. Полностью конфигурируемый с помощью множества комбинаций, идеально подходит для любого применения с подбором…

Новая вакуумная присоска для яиц ECX36 от Piab повышает производительность процессов транспортировки яиц

Обеспечивающая прочный и в то же время бережный захват вакуумная присоска для процессов транспортировки яиц, подходящая для высокоскоростных операций. Опробуйте ее прямо сейчас!