Produzione nutraceutica

I nutraceutici, o integratori alimentari, appartengono a un settore dinamico che affronta diverse sfide. Questi prodotti possono variare da compresse e capsule a polveri e persino gomme da masticare. I produttori spesso devono utilizzare attrezzature di grado alimentare nelle loro linee di produzione e seguire i protocolli cGMP. In ogni caso, i materiali solidi utilizzati possono essere facilmente movimentati con il giusto conveyor a vuoto Piab.

Sistemi per la Produzione di Nutraceutici di Piab

Ecco come i sistemi di trasporto Piab garantiscono una produzione efficiente di nutraceutici e integratori alimentari.

Prelievo di materiali solidi da barili, IBC, sacchi o big bag

La produzione di nutraceutici inizia con il carico degli ingredienti nel processo con il metodo giusto. Piab offre una vasta gamma di accessori, tra cui lance di alimentazione per prelevare materiali da barili o IBC (Intermediate Bulk Container), stazioni di svuotamento sacchi, e opzioni di scarico big bag con adattatori per regolare il rapporto aria/materiale.

Trasporto di nutraceutici verso e da unità di miscelazione e blender, vibrovagli, V-blender e scarico di essiccatori a letto fluido

La miscelazione è un'operazione altamente complessa ed è essenziale avere la giusta soluzione di miscelazione e trasporto fin dall'inizio. Questo aiuta a garantire il controllo completo sui numerosi fattori che influenzano l'efficienza della miscelazione e la qualità del prodotto finale. I sistemi di trasporto Piab svolgono un ruolo fondamentale nel funzionamento efficiente dei processi di miscelazione nella produzione di integratori alimentari, incluso il caso speciale di alimentazione dei V-blender. Inoltre, vengono utilizzati nel processo per alimentare vibrovagli o scaricare essiccatori a letto fluido tra gli altri.

Trasporto del materiale per integratori alla riempitrice di capsule

Dopo la lavorazione primaria, come la miscelazione, la miscela di materiale per integratori, che sia in polvere o granuli, deve anche essere trasportata alle macchine di riempimento. I conveyor Piab trasportano il materiale per integratori alle stazioni di riempimento delle capsule, distribuendolo in modo efficiente.

Anche le capsule vuote devono essere trasferite dai contenitori di stoccaggio alle stazioni di riempimento. I conveyor vengono utilizzati per movimentare le capsule vuote in modo ordinato, garantendo un approvvigionamento continuo alle macchine di riempimento

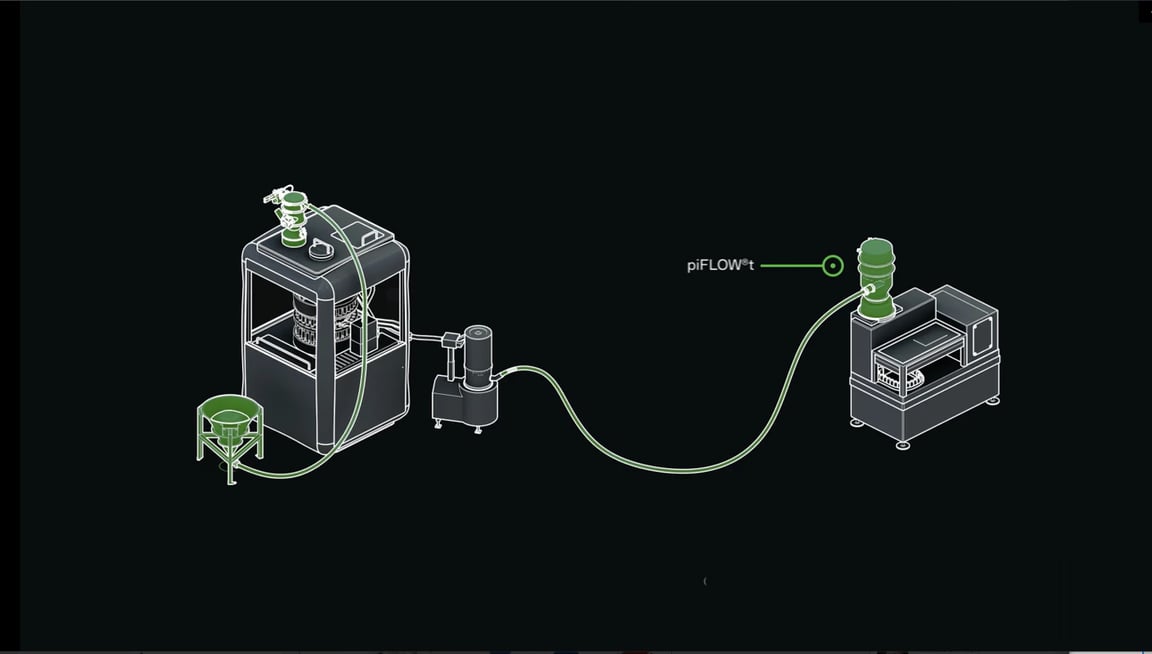

Alimentazione della comprimitrice per compresse

La produttività e l'ergonomia dello spazio di lavoro possono essere notevolmente migliorate grazie al trasporto a vuoto Piab. L'alimentazione della comprimitrice per compresse diventa semplice e le compresse pronte possono essere trasferite delicatamente verso le unità di rivestimento o la linea di confezionamento. L'uso del conveyor a vuoto Piab appropriato evita la segregazione/separazione delle materie prime nei mix e la scheggiatura delle compresse, portando a un aumento dell'efficienza e della produttività.

Riempimento di bustine nutraceutiche

L'azienda austriaca Kora Füll GmbH utilizza i conveyor piFLOW®p per riempire efficacemente i superfood in stick pack. La loro scelta di acquisto si è basata sull'eccellente supporto locale di Piab, sulla facilità di pulizia e manutenzione del sistema di trsporto, e sul miglioramento della sicurezza e del comfort sul lavoro. In questo esempio, il loro conveyor a vuoto Piab opera con una capacità di 500 kg/h, trasportando materiali in polvere fino a 10 metri di distanza.

Confezionamento di integratori e nutraceutici

Dopo che le capsule sono riempite e sigillate e/o le compresse sono pressate e rivestite, vengono solitamente confezionate in flaconi, blister o altri contenitori. I sistemi di trasporto Piab sono utilizzati per trasportare le capsule o le compresse alle stazioni di confezionamento, etichettatura e tappatura per la lavorazione finale prima della distribuzione.

Contattaci.

Ricevi consulenza e consigli gratuiti dai nostri specialisti di automazione su come ottimizzare il tuo processo.

Una soluzione per l'automazione con molte applicazioni

L'industria nutraceutica si posiziona tra il settori alimentare e farmaceutico, coprendo varie pratiche che vanno dalla produzione di alimenti funzionali e integratori alimentari fino alla produzione farmaceutica sterile. Questa varietà implica una diversità di requisiti per l'hardware di produzione, con il mantenimento dell'integrità del prodotto come standard fondamentale. La maggior parte dei sistemi di trasporto deve essere solo di grado alimentare, ma in alcuni casi si applicano regole più rigorose, specialmente se il materiale trasportato rappresenta un rischio per la salute degli operatori.

piFLOW® per l'industria nutraceutica

Piab offre una vasta gamma di conveyor a vuoto per soddisfare tutte queste esigenze, inclusi quelli di grado alimentare e antistatici con certificazioni ATEX per polveri o gas. Per trasportare polveri e granuli, si consiglia uno dei modelli piFLOW®p o piFLOW®c, a seconda della capacità necessaria, delle caratteristiche del materiale e del livello di intervento manuale richiesto dall'operatore durante l'installazione e l'uso continuo.

Il conveyor piFLOW®p è disponibile con quattro diversi livelli di automazione, dalla versione standard all'Auto-tuning completamente automatizzato. Per trasferire compresse o altri materiali più fragili, consigliamo di utilizzare il piFLOW®t, dotato della tecnologia piGENTLE® per evitare la scheggiatura delle compresse durante il trasferimento.

I conveyor a vuoto possono essere impiegati in diverse fasi della linea di produzione, inclusi il carico e lo scarico di comprimitrici per compresse, macchine per il riempimento di capsule, unità di miscelazione e mescolamento, compattatori a rulli e dosatori a coclea fino al confezionamento. Un'idea errata sul trasporto a vuoto è che possa danneggiare il prodotto o causare la separazione nei mix di polveri. Con le impostazioni corrette e la dimensione adeguata, i conveyor Piab superano efficacemente queste sfide, eliminando la preoccupazione per le variazioni nella formulazione del prodotto. Il loro ingombro ridotto consente inoltre una disposizione flessibile.

Era fondamentale per noi che il conveyor potesse essere pulito non solo rapidamente, ma anche a fondo, per evitare che residui del prodotto precedente contaminassero il successivo, specialmente in caso di allergeni, che sarebbero assolutamente da evitare.

Perché scegliere il trasporto a vuoto Piab?

Soddisfa i requisiti

Tutti i conveyor a vuoto Piab soddisfano i vari requisiti applicabili nel settore nutraceutico. I nostri application engineer possono aiutarti a scegliere il sistema ideale da utilizzare.

Garantisce produttività

L'approvvigionamento del materiale non dipende dalle capacità fisiche dell'operatore e consente un processo continuo. Evita la movimentazione manuale, contribuendo anche a migliorare la salute e la sicurezza sul lavoro, aumentando al contempo il tempo di attività del sistema.

Evita la segregazione

I prodotti in polvere rimangono consistenti nel processo di trasporto. Le compresse e le piccole particelle, invece, non verranno danneggiate grazie al processo di trasporto delicatos.

Ingombro ridotto

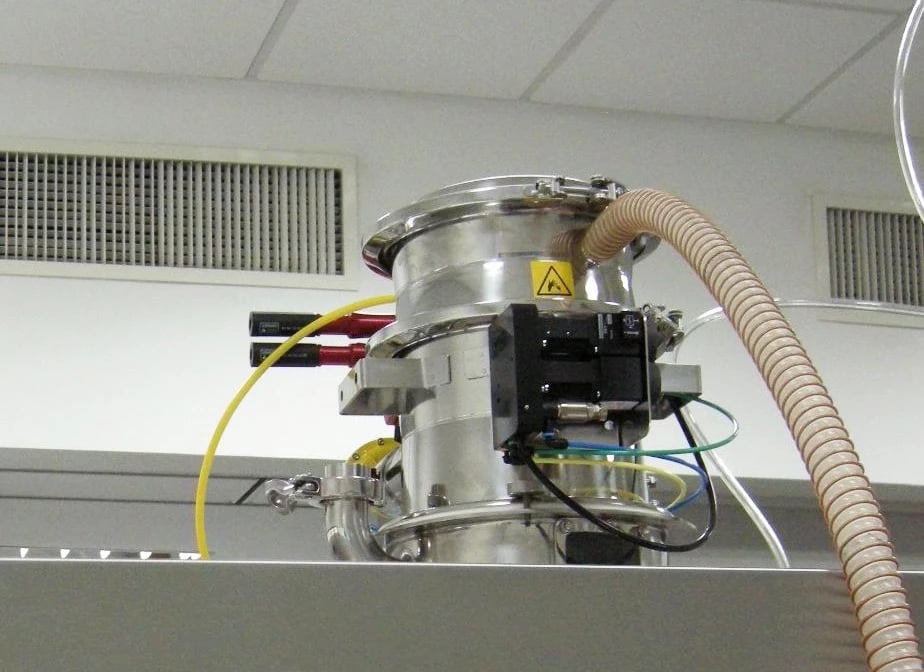

I conveyor a vuoto Piab hanno un design compatto e modulare che consente di adattarli facilmente, manutenerli e pulirli. Si adattano anche a spazi ristretti quando devono essere montati sopra impianti più grandi, come le macchine per il confezionamento.

piFLOW®p in contesti reali

piFLOW®p in manutenzione

Un operatore ispeziona piFLOW®p

piFLOW®p alimenta una macchina per il riempimento di bustine

piFLOW®p

Ottieni supporto nella scelta del sistema di trasporto ideale!

Scopri la soluzione più adatta ai tuoi materiali e prodotti! Compila il modulo per ricevere una consulenza gratuita e personalizzata dai nostri ingegneri, insieme a confronti con altre tecnologie per individuare la soluzione migliore per le tue esigenze.