Oral Pouch Production: Advanced Solutions for Functional Pouches

Piab’s cutting-edge vacuum conveying solutions are transforming oral pouch production lines. No matter if you make nicotine pouches, energy pouches, caffeine pouches, vitamin pouches, or any other oral pouches, our technology guarantees purity. It also ensures flavor consistency and safety for important ingredients like microcrystalline cellulose throughout the entire pouch packaging and manufacturing process. With Piab, you get reliable, hygienic, and compliant material transfer at every stage.

Examples of Applicable Industries & Oral Pouch Types

Do you face dusting that affects operator health? Is it difficult to achieve precise pouch filling or manage pouch sealing? Are your operators climbing stairs to charge pouch machinery? Read further if these challenges sound familiar.

Key Challenges Solved by Piab’s Pouch Technology

Maintaining ingredient purity and batch consistency

Gentle conveying protects sensitive powders like microcrystalline cellulose, ensuring uniformity in nicotine pouches, caffeine pouches, and smokeless pouches.

Ensuring a homogenous blend

Controlled handling achieves consistent mixtures for all oral pouches, from nicotine pouches to vitamin pouches, securing repeatable product quality.

Preventing cross-contamination and protecting operator safety

Closed systems safeguard against flavor and strength mix-ups in alternative nicotine products and tobacco-free pouches, while dust containment and ergonomic solutions reduce health risks.

Efficient scaling with modular pouch technology

Modular, automated pouch packaging and pouch technology simplify line upgrades, supporting smooth capacity increases as your nicotine pouch business grows.

Piab in Every Process Step of Functional Pouch Manufacturing

Piab’s vacuum conveying systems integrate seamlessly with material bag dump and storage stations, mixers, sieves and screeners, pouch filling machines, and automated pouch packaging equipment. Piab is supporting both small-batch and large-scale production and allows for easy scaling when your business grows. Piab conveyors can support a wide range of process steps throughout your production. For example, they can transfer material from the granulator to the dryer, and then continue conveying it from the dryer to the next stage. In addition, there are several other areas where Piab solutions can add value along the line.

The following sections present two example setups that illustrate how Piab conveyors can be integrated into different parts of the process.

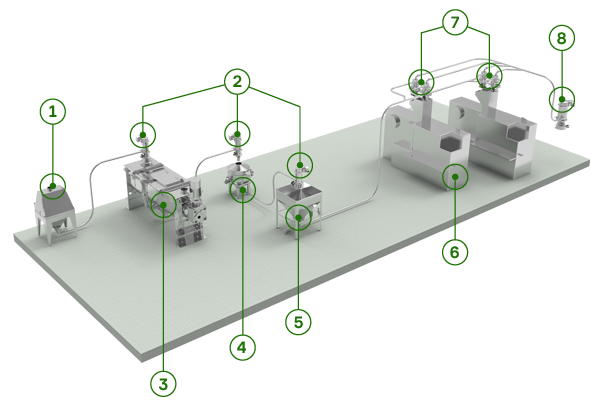

Example Process Setup: From Raw Materials to Multi‑Flavor Packaging

The operator empties raw materials into the Piab bag dump station (1). A Piab piFLOW® vacuum conveyor (2) transfers the material to the horizontal mixer (3). Another Piab conveyor (2) moves the blend to the sieve/screener (4) and into the bin/hopper (5). From there, the system conveys the material to pouch formation and into a high‑performance forming, filling, and wrapping/cartoning line (6) equipped with Piab pre‑separators/cyclones (7) and a single Piab vacuum source (8).

Use this setup for efficient, flexible multi‑flavor production where a small product loss (up to about 0.2%) is acceptable; any loss from this step can be collected and reused.

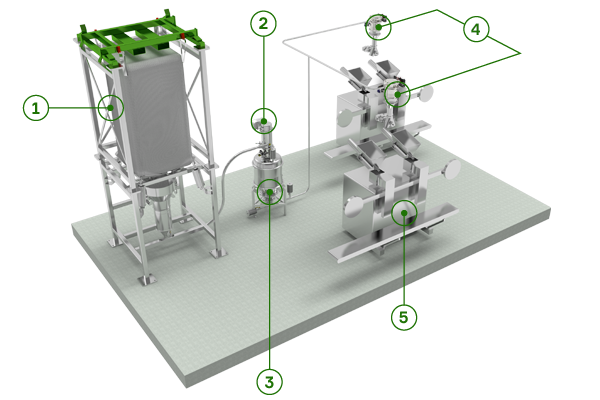

Precision Packaging Line Feeding

From the Piab bulk bag unloader (1), a Piab vacuum conveyor (2) transfers the raw material to a small silo (3) for storage. From the silo, two Piab vacuum conveyors (4) feed the material into the form-fill-seal packaging line (5).

This solution is optimal when no product loss is acceptable. In this setup, each flavor or product variant uses a separate Piab filter in its vacuum conveyor to prevent cross‑contamination.

Typical Materials Handled

Nicotine salt powder for nicotine pouches and tobacco‑free pouches.

Plant‑based fibers (cellulose, eucalyptus, bamboo)

Microcrystalline cellulose for pouch packaging and cellulose‑based carrier systems.

Flavor powders (mint, citrus, berry, coffee, etc.), sweeteners (xylitol, sucralose), aroma enhancers, and colorants.

Moisture regulators such as propylene glycol, glycerol, and HPC.

Entire pouches after filling into packaging.

Combined blends of nicotine, carriers, and additives prepared as ready‑to‑dose premixes.

Materials with etheric oil content or other wet materials (Requires testing in Piab Customer Experience Centers).

Why Leading Producers Choose Piab for Enabling the Production of Oral Pouches

Top manufacturers of nicotine pouches, caffeine pouches, and other oral pouches trust Piab vacuum conveyors for:

Gentle, contained transfer

Protects microcrystalline cellulose and other sensitive ingredients, preventing product loss in pouch filling.

Hygienic design

Meets strict food and pharma-grade standards for cleanroom pouch packaging and cellulose packaging.

Flexible, modular, scalable systems

Adapt quickly to new pouch formats, flavors, and production lines

Sustainable operation

Low energy consumption and minimal maintenance for efficient oral pouch manufacturing.

Global support and warranty

Backed by Piab’s 5-year warranty and worldwide service network for all pouch machinery.

Certified quality

Configurations fulfilling FDA and ATEX requirements are available.

Ready to Optimize Your Nicotine Pouch, Caffeine Pouch, or Other Oral Pouch Production?

Contact our application engineers for a personalized consultation. Discover the perfect vacuum conveying, pouch filling, and pouch packaging solution for your nicotine pouches, caffeine pouches, microcrystalline cellulose handling, and vitamin pouch production line.