Battery Production and Assembly: Handling Solutions

Advanced handling solutions, ranging from early stages of stacking anode and cathode plates in battery and fuel cell production to final unit assembly are all parts of Piab’s advanced offering. We provide custom gripping solutions within the automotive sector as well as a wide range of standardized products which are all designed for light wight, precision, speed and quality.

solutions

Tailored to your exact process needs, Piab’s Custom Line Solutions offer flexible, scalable gripper designs for demanding applications.

reliability

Piab's solutions prioritize process safety, ensuring safe handling of sensitive and potentially hazardous materials.

processes

The solutions of Piab offer a secure yet gentle grip, enhancing cycle times and increasing output volumes.

Mastering Battery and Fuel Cell Manufacturing

with Custom Gripping Solutions

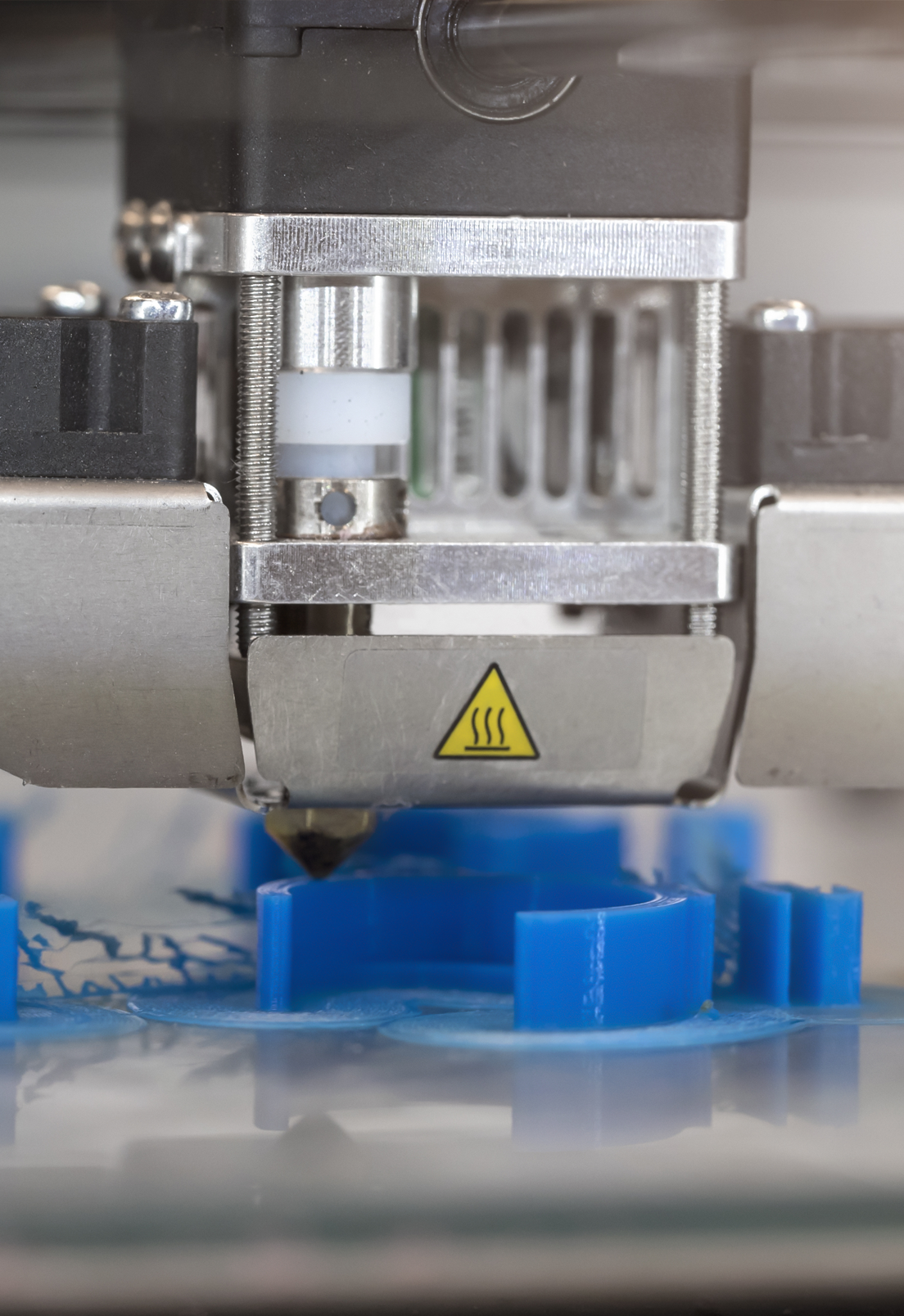

We build custom grippers that fit your battery production process perfectly. Designed for maximum performance, they feature lightweight 3D-printed housings, energy-efficient ejectors, and independent vacuum zones for a safe grip, even during power loss. Modular, scalable, and sensor-ready, our grippers adapt easily to different shapes and sizes while ESD-safe suction cups reduce static electricity.

Let’s build your perfect fit

Looking for a gripper tailored to battery cell or fuel cell handling? Get in touch with our Custom Line team. We’ll design a solution that fits your process, from cell manufacturing to module and pack assembly.

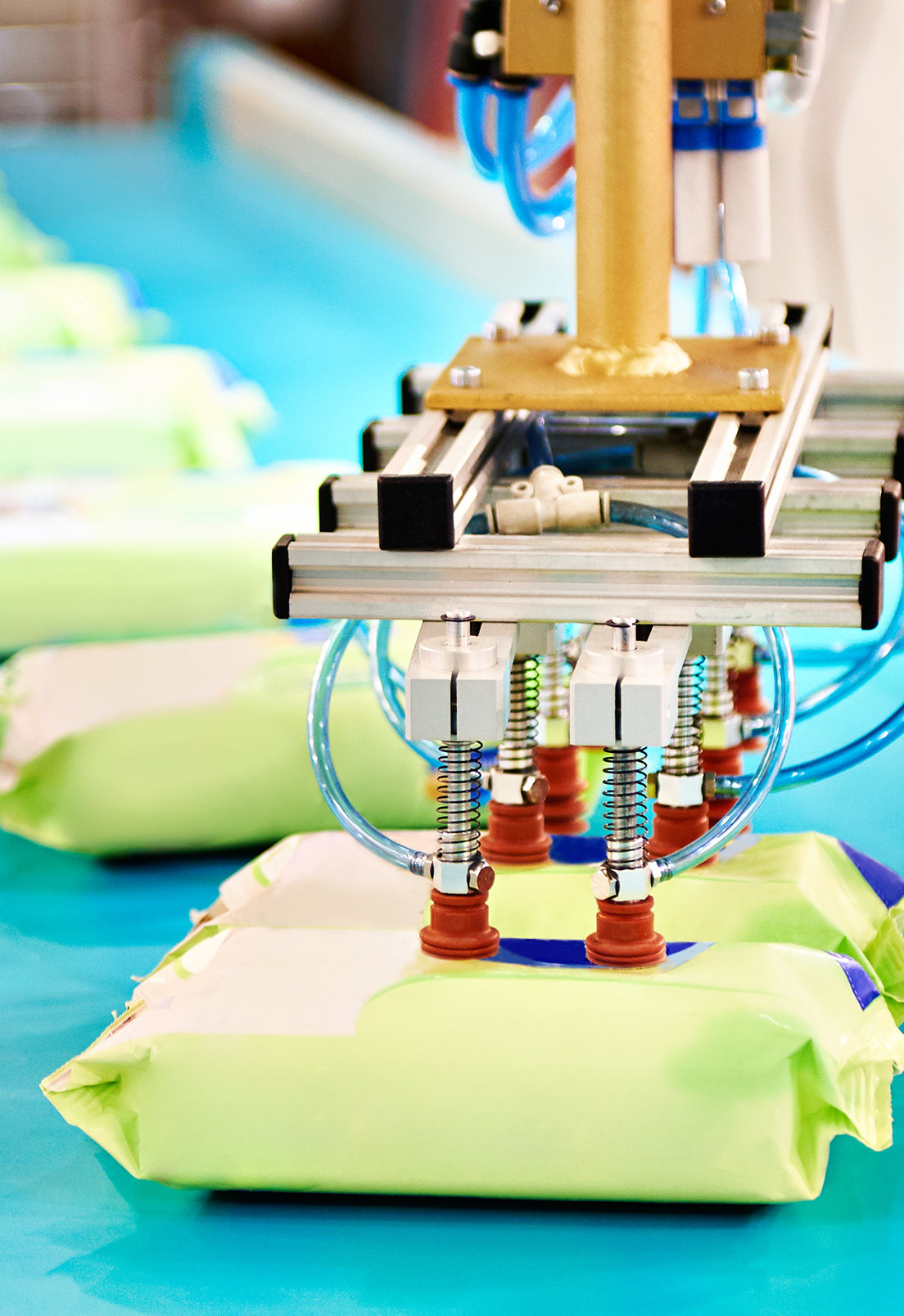

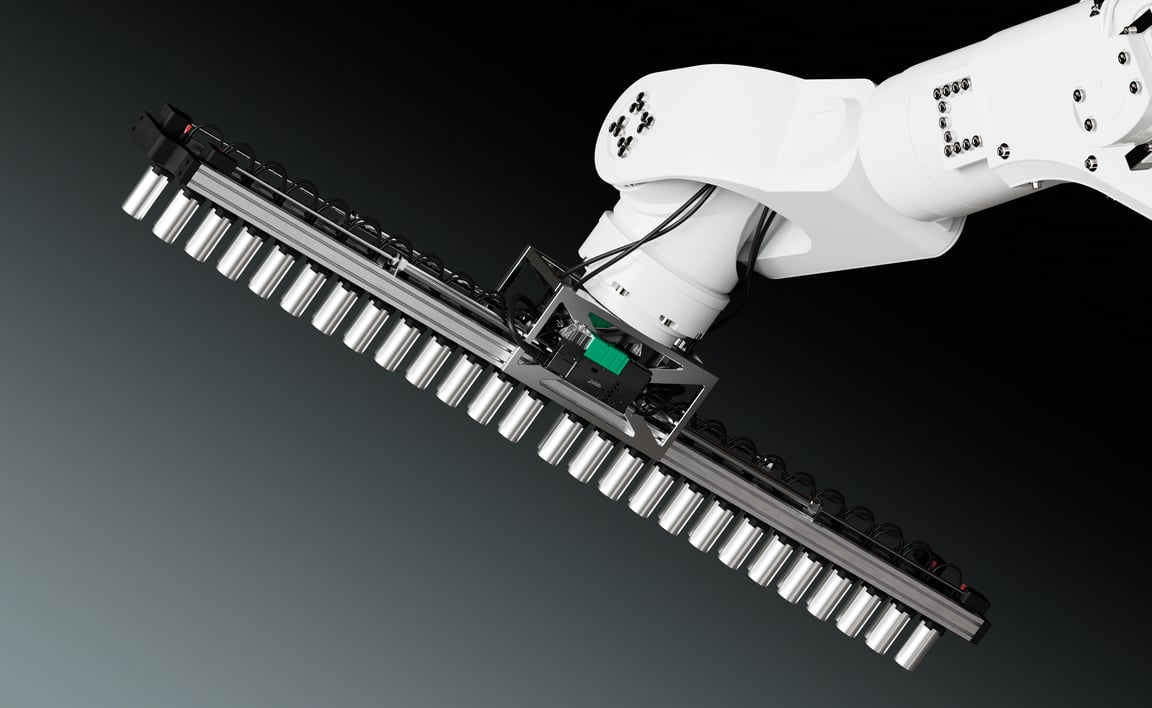

Stack Electrode Sheets with Ease

Handle anodes and cathodes safely, gently and efficiently with our lightweight vacuum grippers. Designed for sensitive battery materials, they feature integrated vacuum zones, optional quick changers and a modular setup for easy adaptation. This supports cost-effective automation, enables faster implementation and allows the use of smaller robots to reduce overall investment.

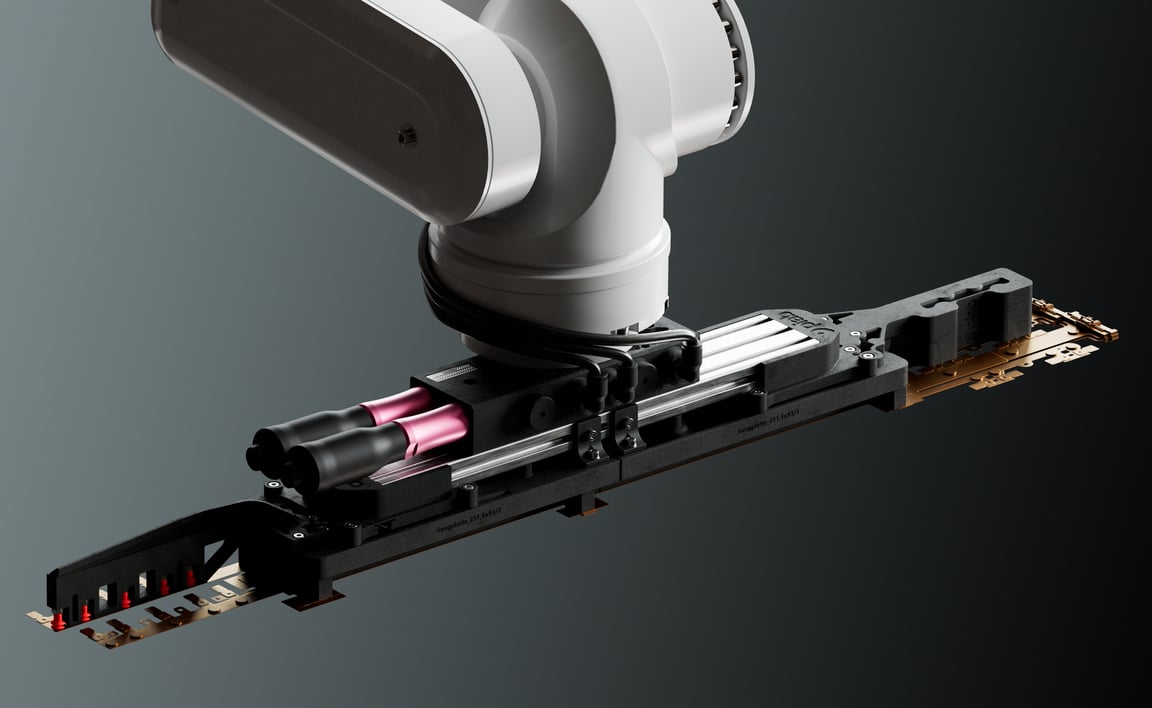

Handle Flexible Printed Circuits (FPCs)

with a strong but gentle grip

Flexible Printed Circuits require handling with extreme care. Our lightweight, modular grippers offer a secure and gentle grip on fragile FPCs – even at high speeds. With a built-in vacuum source and blow-off valve, they enable precise, efficient handling while supporting the use of smaller, cost-effective robots. Customizable designs ensure seamless integration into any production line.

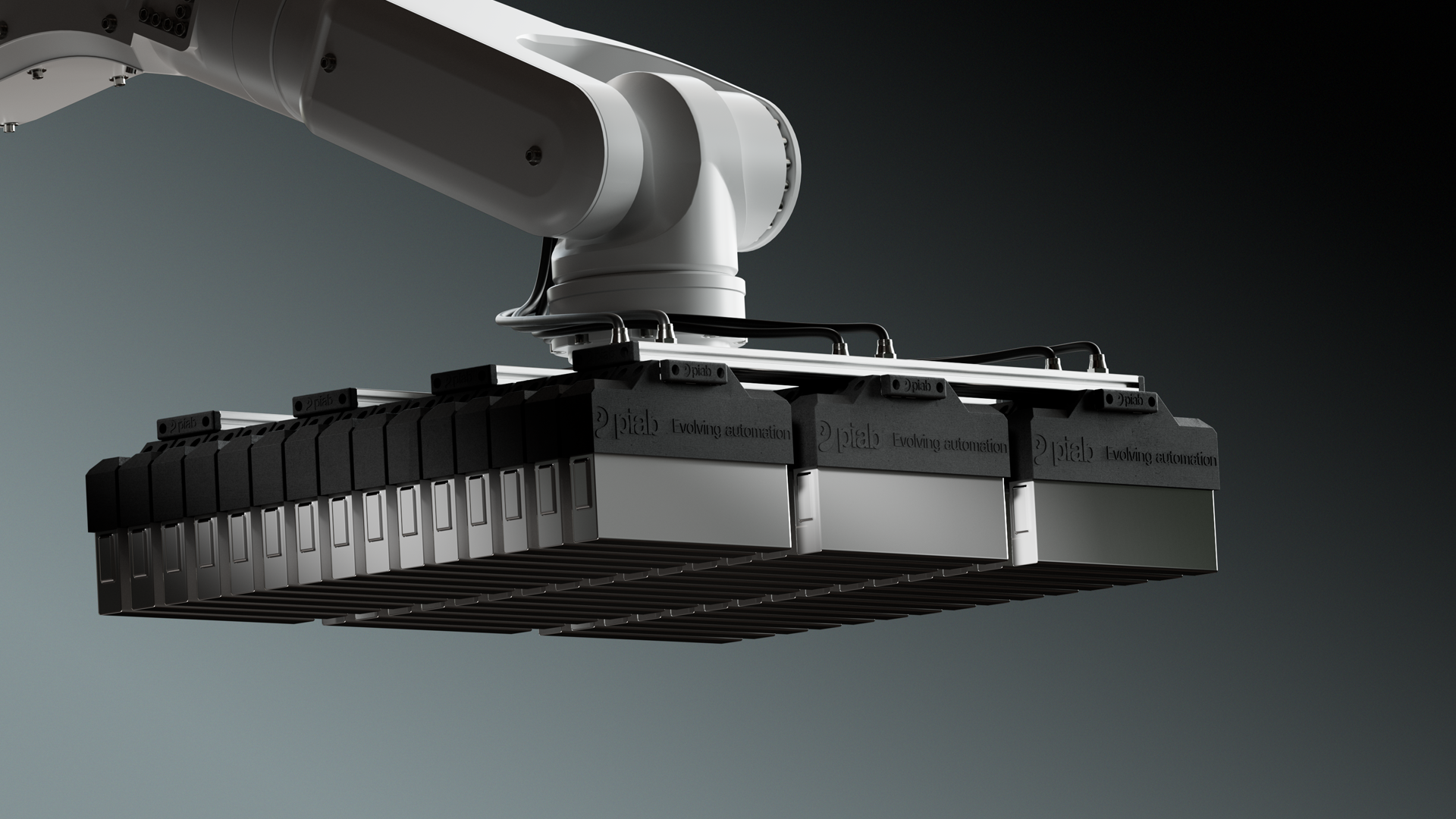

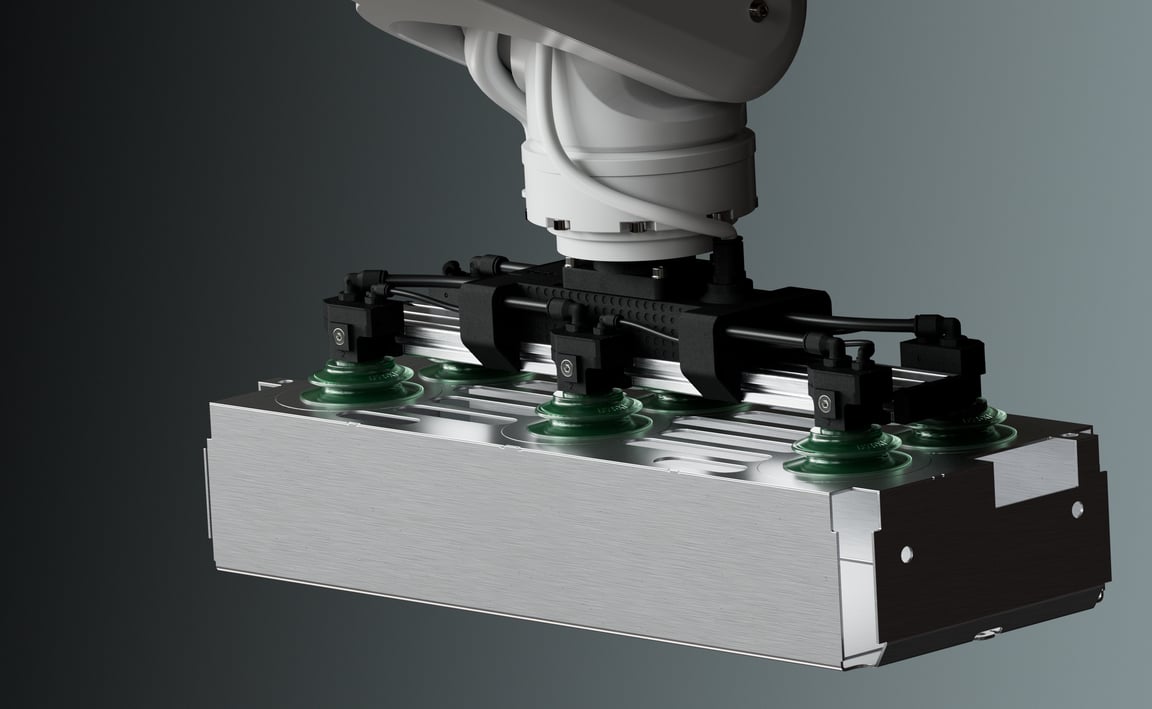

Assemble Battery Modules

with Speed and Precision

From pouch to prismatic to cylindrical cells – our vacuum grippers support reliable, high-speed module assembly with minimal waste and maximum uptime. Dual or multi-zone vacuum technology ensures stable handling, even during fast or complex movements. Thanks to their modular and scalable design, our grippers can be tailored to your specific setup, supporting cell stacking, pad handling and liner removal in one streamlined process. With energy-efficient and multi stage COAX® vacuum technology and gentle, mark-free gripping, we help you build battery modules with efficiency, repeatability and care.

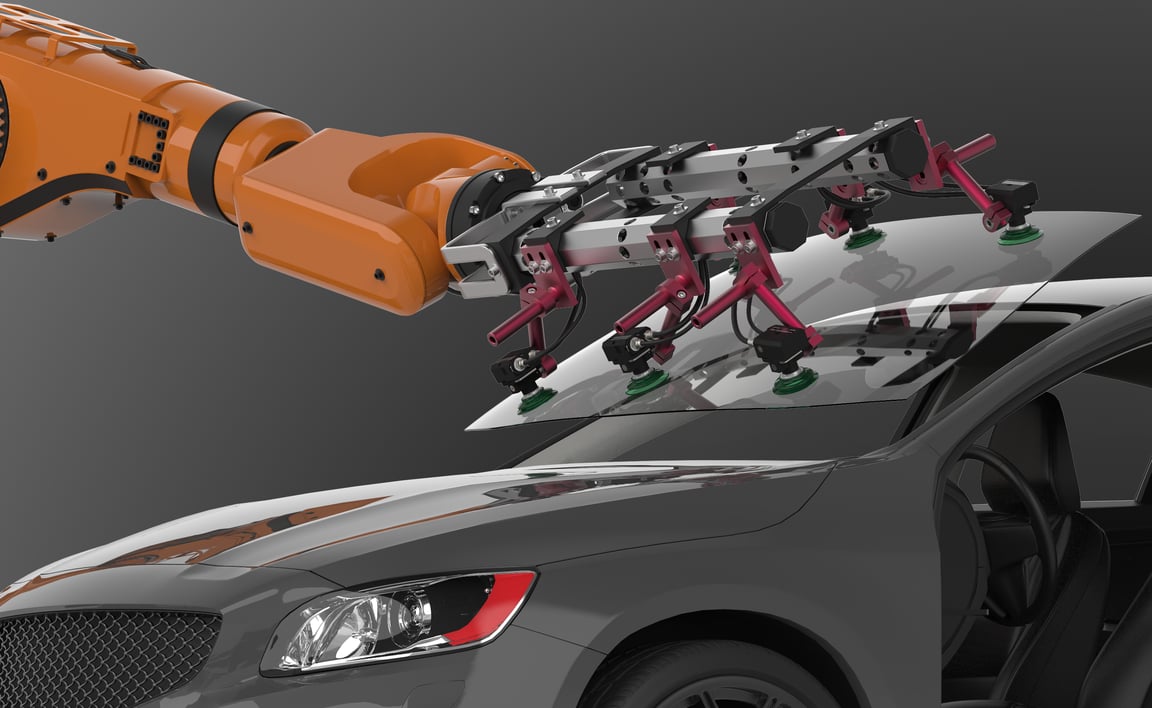

Streamline Pack and Vehicle

Assembly with Confidence

Our gripping solutions support precise, safe and efficient handling throughout the final stages of battery assembly. Whether you're transferring heavy modules, handling trays or installing packs into vehicles, our lightweight and modular grippers adapt flexibly to varying shapes and weights. Friction cups and integrated vacuum traps ensure a secure grip, even during air loss, while multi-zone vacuum setups enhance safety and uptime. With one tool covering multiple tasks, you reduce robot count, save space and boost overall efficiency in battery and fuel cell system installation.

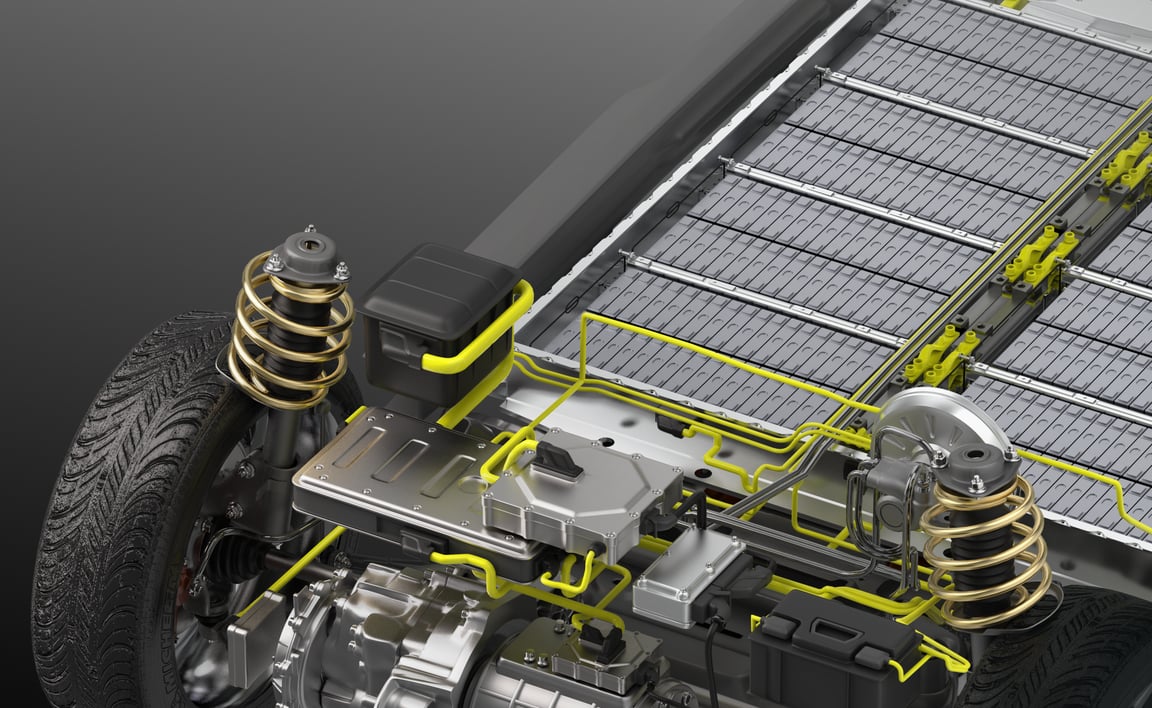

Components for Your Battery Production Setup

Looking to build your own system? Our standard components give you the flexibility to design efficient, reliable battery handling solutions. Choose from high-performance suction cups, energy-efficient ejectors and smart accessories – all built for precise and safe operation. Easy to integrate and ready to perform, they support smooth processes across every stage of battery and fuel cell production.

Not sure what to choose?

If you need help selecting the right components, our experts are here to help. Contact us for advice on standardized products and ready-to-use solutions.

Reliable Grip for Every Surface

From delicate battery components to metal sheets – our suction cups deliver safe, stable handling across all surfaces. Modular and highly adaptable, With a wide range of configurations and high adaptability, they support precise lifting and level adjustment for objects of various sizes, shapes, and sensitivities. Choose from a broad selection of materials, sizes, lip types, and ESD-safe options to meet the exact demands of your battery or fuel cell production process.

Efficient Vacuum Generation Made Simple

Boost the performance of your battery and fuel cell production with Piab’s ejectors. Powered by energy-efficient, multi-stage, COAX® technology, they deliver reliable vacuum generation even in demanding environments. From the intelligent, compact and stackable piCOMPACT® with integrated control to the safety-focused, fully pneumatic, decentralized piSAFE®, our range supports fast cycles, reduced air consumption and safety.

Optimize Performance with Smart Accessories

Enhance system efficiency, safety and control with our range of accessories designed for battery and fuel cell handling. Blow-off check valves ensure faster response times and reliable product release, even in larger systems with minimal pressure. Vacuum switches offer flexible control options and easy installation. All components are lightweight, durable and engineered for smooth integration into your automation setup.

FAQ: Piab's Battery and Fuel cells Solutions

How can Piab's solutions improve efficiency in battery and fuel cell manufacturing?

Piab develops components and lightweight grippers for battery and fuel cell manufacturing. The optimized vacuum systems and components enables high speed handling with precision and high quality.

In which applications do Piab offer solutions for battery and fuel cell manufacturing?

Piab offers solutions for handling Anode and cathode sheets, Flexible Printed Circuits (FPC), Pouch cells, Cylindrical cells, Prismatic cells, Pack assembly, Mono/Bi-polar plates and many more.

Is it possible to save energy while you automate your battery manufacturing and assembly?

Energy can be saved by using Piab's vacuum pumps featuring efficient COAX® technology, built in energy-saving functions, and integrated controls.

How do I get started with Piab's battery and fuel cell solutions?

To get started, you can contact Piab directly or reach out to your local Piab distributor. Piab's experts can provide detailed information, product recommendations, and support to help you implement the best solutions for your battery and fuel cell operation.

Can Piab's solutions handle a thin and fragile sheets and products?

Yes, Piab provides grippers that ensure precise and efficient handling of fragile components like FPCs.

What customization options are available for Piab's grippers?

Piab's grippers are modular and scalable, allowing for customization to meet specific customer needs for handling different cell types and sizes.

How do Piab's vacuum solutions create a safe and efficient battery assembly operations?

Piab offers vacuum grippers that provide a secure grip, even during power failures, ensuring safe handling of valuable materials.

Are Piab's solutions compliant with industry standards?

Yes, all Piab's products and solutions comply with various industry standards and regulations.

Explore more vacuum automation solutions and industries

Need guidance? We're here to help.

Get expert support for your battery production or fuel cell manufacturing process. Fill out the form to learn more about our battery handling systems and solutions for new energy systems.