Manutention automatique et sûre de plaques de verre grâce à la technologie du vide de Piab

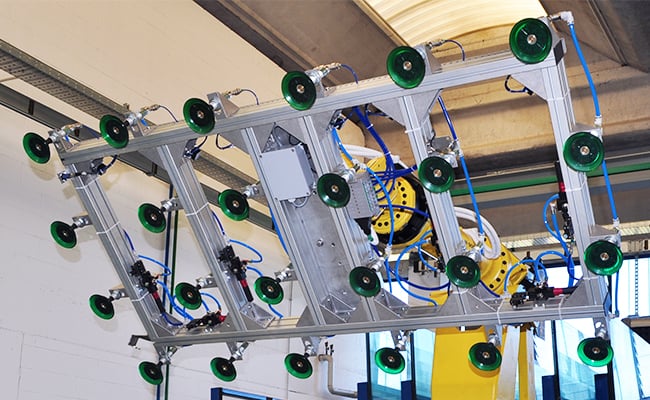

À l’aide des ventouses à haute friction DURAFLEX® de Piab, des générateurs de vide VGS™5010 et des appareils piSAVE®, Forvet SpA a créé des accessoires de préhension (EOAT) qui permettent de manipuler des plaques de tailles variables dans son système de pointe de traitement du verre COMBIFLEX, installé chez une grande multinationale du secteur du bâtiment.

Le système COMBIFLEX de Forvet est considéré comme un joyau de la technologie, en fusionnant six machines en une, ce qui assure simultanément le broyage, le fraisage, le perçage, le lavage et le séchage du produit fini.

Les produits de Piab permettent le chargement et le déchargement automatiques des plaques jusqu’à la fin des opérations effectuées par le système. Dans le châssis du chargeur de plaques, des ventouses DURAFLEX® saisissent le verre en position verticale depuis un rack de machine et le placent en position horizontale sur l’établi de la ligne. Les mêmes ventouses positionnées sur les châssis de déchargement automatique saisissent le verre en position horizontale depuis l’établi de la ligne et le placent en position verticale sur le rack de machine.

Les ventouses manipulent des plaques d’une épaisseur de 3 à 19 mm, ce qui peut représenter un poids important en fonction de la taille des plaques de verre. Le verre est chargé automatiquement à 100 %, ce qui permet d’éviter les risques liés aux opérations manuelles. Le chargement et le déchargement manuels du verre de taille et de poids importants ne seraient pas possibles pour un seul opérateur sans le recours à un équipement spécifique, ce qui entraînerait des limitations et des délais prolongés de chargement / déchargement, sans parler du risque de casse des produits.

Avec les composants de Piab, Forvet a pu augmenter sa productivité grâce à la fiabilité absolue de préhension des solutions fournies, améliorant ainsi l’ergonomie des machines et permettant au client final de bénéficier d’économies d’énergie considérables.

Dr. Francesca Gariglio, directrice marketing et coordinatrice des ventes chez Forvet déclare : « Nos machines fonctionnent dans des environnements humides et manipulent des plaques de verre qui sont des éléments fragiles. Nous devons être certains que la préhension est optimale et fiable. Nous ne pouvons pas nous permettre de dysfonctionnement lors du prélèvement du verre, et encore moins lors de son déchargement après le traitement. C’est pourquoi, nous avons choisi un partenaire fiable comme Piab. »

Eng. Gallo, technicien de Forvet, ajoute : « Nous collaborons avec Piab depuis un certain temps déjà. Nous connaissons leurs générateurs de vide et leurs ventouses DURAFLEX® puisque nous les avons utilisés sur nos autres systèmes de traitement du verre tels que FORBOT et KEY. Nous collaborons de manière professionnelle avec les techniciens de la filiale italienne. Nous apprécions leur grande réactivité, leur engagement dans la résolution de problèmes, leur respect des délais de livraison et leurs conseils en termes de démarrage de nouveaux systèmes. Pour nous, c’est essentiel, au même titre que la qualité du produit. C’est la raison pour laquelle nous avons choisi Piab. »

Les ventouses DURAFLEX® de Piab sont idéales pour la manutention de surfaces plates car elle offrent une excellente stabilité de préhension et une force de friction élevée. Elles sont fabriquées en DURAFLEX® durable, un matériau breveté spécialement développé par Piab qui associe l’élasticité du caoutchouc et la résistance à l’usure du polyuréthane. Ce matériau est particulièrement adapté pour le contact avec les plaques de verre en raison de ses propriétés sans marque.

Les générateurs VGS™5010 sont équipés de la technologie de génération de vide COAX® de Piab, qui réduit la consommation énergétique tout en offrant une préhension rapide et sécurisée en raison de son débit d’air aspiré initial élevé. L’unité de pompage peut assurer des performances élevées même avec une pression d’alimentation faible ou fluctuante. Cela a été prouvé par des tests comparatifs indépendants effectués à l’Institut Fraunhofer IWU de technologie du formage et des machines-outils de Dresde. Ces tests ont montré que les éjecteurs de Piab utilisent beaucoup moins d’air comprimé pour obtenir les mêmes résultats que des éjecteurs d’autres fabricants. Par conséquent, l’utilisation des éjecteurs de Piab permet de réduire le coût de l’alimentation en air comprimé et, donc, le coût total de production.

Les appareils piSAVE® de Piab sont montés sur les générateurs de vide VGS™5010 afin de réduire davantage la consommation d’air. La fonction piSAVE® ON/OFF permet d’économiser l’air comprimé en interrompant l’alimentation pneumatique des générateurs lorsque le niveau de vide souhaité est atteint, tandis que les ventouses maintiennent leur prise. La fonction piSAVE® Release permet une libération rapide du matériau manipulé sans signaux de pilotage et sans consommation supplémentaire d’air comprimé.