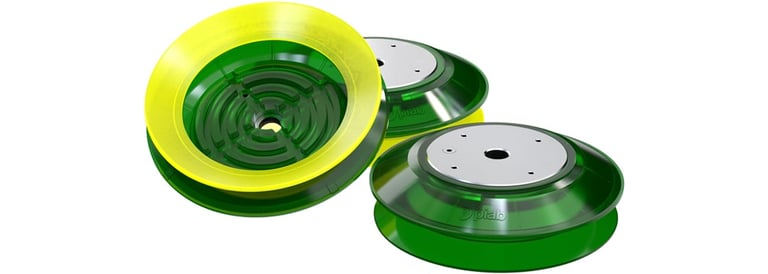

Piab adds new sizes to its Bellows Polyurethane suction cup family: B150P and B200P

Further broadening its already extensive application range, Piab expands its line of Bellows Polyurethane suction cups to include cups measuring 150 mm and 200 mm in diameter.

With their short bellows, these Bellows Polyurethane (BP) suction cups are ideally suited to handle objects of different height when joined in one lifting device – an important feature when handling wooden parts for furniture production. The suction cups are available being made out of 60 shore material completely or with a 60 shore bellow and a 30 shore lip. While the latter is ideal for handling rough or structured surfaces of for instance unworked wood, the 60/60 shore version is perfect for handling smooth, non-leaking flat surfaces like those of glass, metal sheets, painted or coated wood panels such as finished furniture parts. Thanks to their capability of handling leakage prone materials such as cartons these Bellows Polyurethane suction cups are also suitable for handling large boxes in packaging and palletizing applications.

The suction cups are equipped with a plug for connection of a sensor to allow measuring the vacuum level reaching the respective suction cup. For rigidity considerations, an aluminum plate for direct attachment to the tool flange or EOAT profile is integrated, preventing the fitting to be affected by bending forces.

The suction cups are made of DURAFLEX®, a unique material made especially by Piab, which features the elasticity of rubber and the wear resistance of polyurethane. DURAFLEX® suction cups allow for stability and good grip independent of the orientation. Furthermore, they offer a long-lasting elastic memory, further enhancing their longevity.

Customer benefits at a glance:

- Enable handling parts with different heights when combined in one lifting device

- Allowing movements in all directions thanks to the strong grip of DURAFLEX® material

- Low downtimes thanks to the high wear resistance, long lasting elastic memory and an integrated aluminium plate protecting the fitting from bending forces

Application areas:

- Wooden parts handling in furniture production

- Glass panel handling

- Metal sheet handling

- Packaging and palletizing

- Automotive components assembly