Elevate Safety and Efficiency with Piab's ATEX equipment

When selecting equipment for environments with potential explosive atmospheres, ensuring compliance with ATEX directives is critical. ATEX, short for "ATmosphere EXplosible," refers to the European Union directives that regulate equipment used in explosive atmospheres. For engineers and operative managers considering Piab's ATEX conveyors, understanding ATEX certification is important to ensure safety, compliance, and operational efficiency.

Piab's Commitment to Safety and Compliance

Piab has been a leader in providing ATEX-certified equipment, including ATEX conveyors and ATEX machines, since 2004. We design our ATEX conveyors to safely transport dry powders and granules that can form explosive dust clouds. A third-party organization certifies Piab's ATEX-approved equipment, ensuring it meets stringent safety standards. Piab offers over 300 different configurations of ATEX-approved units, allowing for a tailored approach to meet specific operational needs.

Key Features of Piab's ATEX-Certified Equipment

Antistatic materials

All seals, rubber parts, and main plastic components are available in antistatic materials to prevent the accumulation of static electricity, which is essential to avoid any sparks.

Complete system design

Our ATEX machines include essential components such as pumps*, filters, inlet modules, and bottom valves, ensuring a comprehensive solution for explosive environments. /*Vacuum conveyors with ejector pumps are accepted for ATEX classification; those with mechanical pumps are not.

Areas of application and industries

Pharmaceuticals and chemical manufacturing

In pharmaceuticals and chemicals manufacturing, reactor filling is a common challenge due to the presence of explosive volatile gases. Filling must be done securely and automatically. The vacuum conveyor (VC) itself will not produce a hazardous zone as it is sealed, allowing it to be placed in potentially explosive environments. The piFLOW® conveyors, particularly models like piFLOW®p and piFLOW®t, are designed to handle such conditions with ATEX compliance, ensuring safe and efficient operation.

Explosion risk in the food industry

In the food industry, conveying ingredients such as sugar, starch, stabilizers, dextrin, or flour is made possible without explosion risk with Piab vacuum conveyors.

As an example, ingredients can be conveyed from a bag dump station, with a vacuum conveyor feeding a vertical mixer with a flour mix. Then, another vacuum conveyor transfers the mix to an auger filler (as on the image). The piFLOW®fc series is ideal for these applications, offering dust-free and hygienic conveying solutions that meet both ATEX and food-grade standards.

Cosmetics industry

In the cosmetics industry, handling organic thickeners, vitamin powders, or sunscreens as additives requires precise and safe conveying solutions. The piFLOW®i and piFLOW®f models are suitable for these applications, providing efficient and safe transport of sensitive materials. Additionally, in the chemical industry, these conveyors can handle waxes, plastic powders, organically coated fillers, cellulose fibers, and gas-filled lightweight fillers, supporting dispersing and mixing applications.

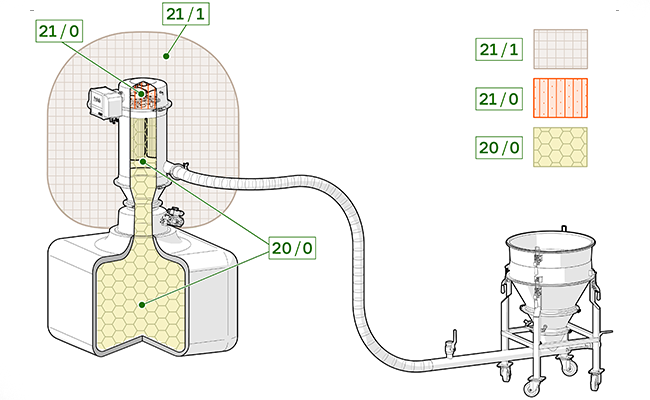

Using Piab in cleanrooms

When you plan your setup in cleanrooms, it is more important than ever to avoid any ignition sources from your equipment in the room. In this example, a piFLOW unit is filling a hopper. Piab ejector pumps meet ATEX-requirements, but the pump can also be mounted remotely. The interior of the conveyor is suitable for Zone 20 or 0, while the exterior can handle Zone 21 or 1, ensuring comprehensive safety across different environments.

ATEX basics - What is an ATEX Certification?

ATEX certification is a mandatory requirement for equipment used in environments where explosive atmospheres may occur. This includes areas where dust, gas, vapor, or mist can form explosive mixtures. The ATEX Directive 2014/34/EU outlines the key health and safety rules for ATEX mechanical and non-electrical equipment. This equipment serves in hazardous environments.

Understanding ATEX Zones and Equipment Categories

ATEX certification involves classifying areas into zones based on the likelihood and duration of explosive atmospheres and specifying ATEX equipment protection levels. Piab Vacuum Conveyors can be placed in Gas zones as well. They can also handle hybrid mixtures in environments with both Dust and Gas, where mixtures can be explosive, for ex. when handling metal powders in certain gas mixtures, or when pharmaceutical powders are conveyed in various gas types.

ATEX Dust and Dust & Gas zoning overview shown on the Piab piFLOWp 33 conveyor:

Dust Zones:

- Zone 20: Explosive atmosphere present frequently or continuously.

- Zone 21: Likely to occur occasionally during normal operation.

- Zone 22: Not likely during normal operation but may occur for short periods.

Dust & Gas Zones:

- Zone 0: Explosive atmosphere present frequently or continuously.

- Zone 1: Likely to occur occasionally during normal operation.

- Zone 2: Not likely during normal operation but may occur for short periods.

Piab vacuum conveyors and parts meeting ATEX requirements

ATEX Equipment Categories:

- Category 1: For the most hazardous zones (0, 20); requires external certification.

- Category 2: For mid-level hazard zones (1, 21); requires notified body involvement.

- Category 3: For least hazardous zones (2, 22); allows self-certification.

Piab offers vacuum conveyors in both Category 1 and 2.

Piab vacuum conveyors can be configured to meet different ATEX categories depending on the specific requirements and the zones they are intended for. They offer a comprehensive product range that can include configurations for various categories, ensuring they meet the necessary safety standards for use in potentially explosive atmospheres. The equipment is designed not to contain any ignition source in normal, prescribed service, adhering to ISO EN 80079-36 and ISO EN 80079-37.

piFLOW®p for Zone 20, 21, 22 and 0, 1, 2 (Gas and Dust)

piFLOWp is made out of SS316L, making it Piab’s premium line of vacuum conveyors with the widest available capacity range. Entire EX marked configurations are available.

Highest level of EX classification for piFLOWp:

- ATEX Dust: EX II 1/2/2 D Ex h IIIC T80°C Da/Db/Db | 0°C ≤ Ta ≤ +60°C

- ATEX Dust &Gas: EX II 1/2/2 D Ex h IIIC T80°C Da/Db/Db | EX II 1/1/2 G Ex h IIB T6 Ga/Ga/Gb | 0°C ≤ Ta ≤ +60°C

piFLOW®i and f for Zone 20, 21, 22 (Dust)

In this configuration, the conveyor can be equipped with explosion-proof components to handle occasional occurrences of explosive gas atmospheres. The system is available with proper grounding and bonding to prevent static discharge.

While the piFLOW®i shares similar features, the piFLOW®f is specifically tailored for food safety compliance meeting FDA requirements.

Highest level of EX classification for piFLOWf and i:

- ATEX Dust: EX II 1/2 D Ex h IIIC T80°C Da/Db

piFLOW®fc for Zone 20, 21, 22 (Dust)

This product family is made out of SS304, a heavy-duty conveyor for various needs.

Configurations are available including antistatic (dissipative) materials for all seals and rubber parts to prevent static electricity build-up, which could ignite dust. Setups are available including a complete machine with a vacuum pump, filter, inlet module, and bottom valve.

Highest level of EX classification for piFLOWfc:

- ATEX Dust: EX II 1/2 D Ex h IIIC T80°C Da/Db

piFLOW®t for Zone 20, 21, 22 and 0, 1, 2 (Gas and Dust)

Available setups are designed for areas where a cloud of combustible dust is not likely to occur in normal operation but, if it does, will persist only for a short period. It incorporates antistatic materials and proper grounding to minimize ignition risks, configured with a vacuum pump, filter, and other components.

Highest level of EX classification for piFLOWt:

- ATEX Dust: EX II 1/2 D Ex h IIIC T80°C Da/Db

- ATEX Gas: EX II 1/2 G Ex h IIB T6 Ga/Gb

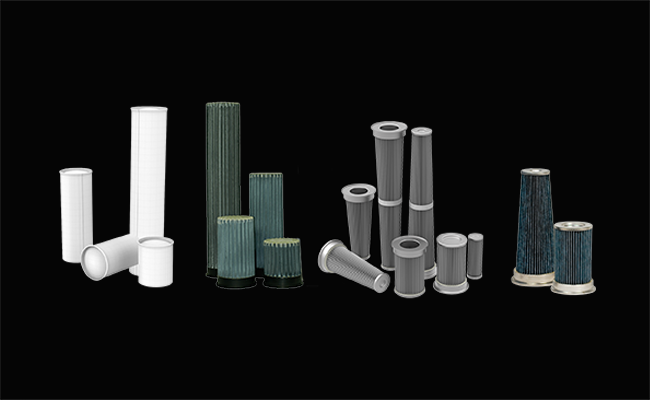

Spare parts and accessories

- Filters: Various filters are available, including pleated and textile filters, designed to meet specific ATEX requirements. The choice of filter depends on the material being conveyed and the specific ATEX zone classification. In ATEX Dust and Gas IIB the available option is the pleated rod filter.

- Sealings: All NBR sealings are used for their antistatic properties, ensuring safety in explosive environments.

- Pumps: Various pumps meet ATEX reqirements. Choose piPremium to meet ATEX Dust, Dust and Gas requirements. Choose piBASIC for ATEX dust applications (not recommended for ATEX dust & gas environments).

*The piGentle feature is not suitable for explosive environments.

Benefits of Choosing Piab's ATEX-Compliant Equipment

Enhanced Safety

Piab's ATEX conveyors are designed to mitigate ignition risks, ensuring a safer working environment. The design incorporates dissipative materials, ensuring that even in potentially explosive atmospheres, the risk of ignition is minimized.

Meets Regulations

By choosing ATEX-certified equipment, you ensure adherence to EU regulations, avoiding potential legal and operational issues. Piab's ATEX conveyors are Ex-marked and meet the machinery directive.

Operational Efficiency

Our engineers design Piab ATEX mechanical equipment for reliability and efficiency, which minimizes downtime and maintenance costs. Not only they are safe for use in explosive environments, but also boost productivity.

Versatility

With thousands of configurations available, Piab offers solutions tailored to specific operational needs and environmental conditions. Configure your conveying solution today!

For operators in industries prone to explosive atmospheres, selecting ATEX-certified equipment from Piab ensures safety, compliance, and efficiency. We dedicate ourselves to quality and follow regulations which makes us a trusted partner.

We provide solutions that fit the unique challenges of your operations. Invest in equipment that ensures piece of mind and operational success. Meet and exceed safety standards by choosing Piab.

Configure your ATEx-marked vacuum conveyor here

Consult with our experts about ATEX vacuum conveyors

Fill out the form and we get back to you as soon as we can.