News

Filter Monitoring Enables Preventive Maintenance

Sustainable Progress in Powder Conveying: Supporting Resource Efficiency and Reduced Energy Use

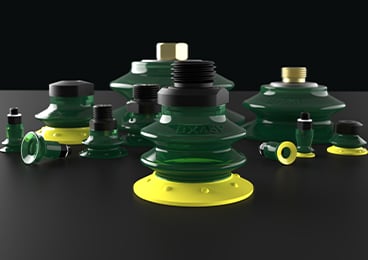

New Sizes for Piab's Bag Opening Cups

Piab is excited to announce the expansion of its acclaimed Bag Opening Cups lineup with the introduction of two new sizes: 18mm and 42mm...

Introducing New Sizes to the BXP Family

Our acclaimed BXP cups, designed for handling porous as well as nonporous surfaces, now include 6mm and 8mm sizes...

Piab Introduces piCLASSIC™ Neo

Piab proudly unveils piCLASSIC™ Neo, the latest evolution of its widely recognized piCLASSIC™ vacuum pump. Designed to meet the evolving demands of modern industries.

Introducing Polyscope X Compatibility: Enhancing UR Robots with Piab Solutions

Polyscope X compatibility marks a significant advancement in the capabilities of Universal Robots (UR), enabling a seamless transition to more efficient and flexible automation solutions.

piCOBOT® Electric now available with seamless integration to FANUC CRX

The fully electric, slim-designed piCOBOT® Electric continues to redefine cobot applications by eliminating air tubing and cabling.

piCOBOT® and piCOBOT®L Now available with plug & play configuration for ABB GoFa

We now offer piCOBOT® and piCOBOT®L with fully ABB GoFa-adapted plug-in versions, delivering true Plug & Play functionality.

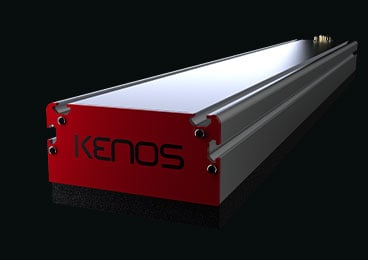

Tailored for success: Meet the new KVG E-Series

The newly developed KVG E-Series embodies Kenos®’ commitment to delivering cutting-edge solutions tailored to diverse industrial needs.

Custom tool CPT now a configurable product

After two successful years as a custom line product, cobot palletizing tool CPT is now due for a move to the standard assortment.

piGRIP® FLC expands Piab’s suction cup universe

piGRIP® FLC is a new component, an interface, that expands the usability of all existing Piab suction cups.

piCOMPACT®23 SMART now available with IO-link Class B

Piab extends the piCOMPACT23 SMART program with IO-link Class B equipped with separate power domains between actuator power and the sensor power.

Piab revolutionizes vacuum system configuration with OVM Pro 3D tool

Piab has launched its highly anticipated OVM Pro 3D, a cutting-edge on-line tool designed to transform the way vacuum systems are configured, simulated and optimized.

New BXP ESD cups move batteries to safer ground

BXP ESD is a new series of modular suction cups, developed to protect sensitive components in batteries, fuel cells and electronics from electrostatic discharge during handling.

piSAFE® - now even safer

As piSAFE® is now upgraded the safety focus remains, however with versatility and sustainability as new companions.

piCOBOT® Electric breaks the barriers of cobot arm movement

Fully electric, slim design and absence of air-tubing and cabling. The new piCOBOT® Electric heads towards another success for Piab's piCOBOT® program.

Piab Locations on the Move

New BXP 45mm suction cup accompanied by 65 and 90 mm versions

Our recent 45 mm cup for the BXP segment is now accompanied by 65 and 90 mm versions.