Piab 博客

20 篇文章

2024/7/11

从不模仿,亦从未被超越。

X-Factor 访谈 – 隆重介绍 MX 吸盘开发的幕后英雄! Lennart Ryberg – 真空自动化部门全球产品经理 – Piab 任职 2.5 年

2024/7/11

摸清客户需求的差距

X-Factor 访谈 – 隆重介绍 MX 吸盘开发的幕后英雄! Johnny Skagersjö – 自动化部门高级应用工程师,系统工程和研发团队成员,2004 年起入职 Piab

2024/7/11

“Lagom” – 不是最好,但是恰好

X-Factor 系列 – 隆重介绍 MX 吸盘开发的幕后英雄! Gustaf Wigren – 在 Piab 任职 13 年,担任产品技术总监,负责概念系统设计、研发、自动化部门

2023/4/6

四十余载,依然在路上 - 一段有关输送机的传奇还在延续

为庆祝 Piab 成立 70 周年,真空输送事业部发起了一场竞赛,以寻觅最古老、仍在役的 Piab 真空输送机。而这最终“花落”……

2021/8/10

德国工业面包店 Austerschmidt 采用 Piab 的真空输送机搬运种子

员工的轻松与对资源的谨慎使用促使德国工业面包店Austerschmidt 将种子的搬运从人工转变为自动过程。在piFLOW®f 真空输送机里,他们找到了关键的工具。

2021/4/22

唇边越薄抓取力越好

X-Factor 系列 – 隆重介绍 MX 吸盘开发的幕后英雄!Jonas Herrström – 自动化研发部概念系统设计团队高级设计工程师 – 在 Piab 工作 8 年

2019/11/14

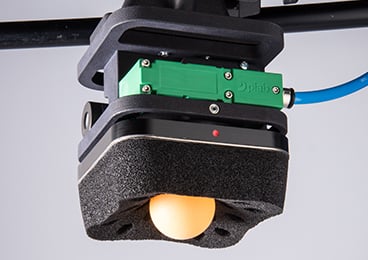

博客: 协作的重要性

协作式机器人可增强人类与机器之间的协作,为成功实现协作,协作式机器人需要使用巧妙设计的臂端工具 (EOAT)。Piab 的 piCOBOT® 就是这样的一款巧妙 EOAT。