Automotive

Press shop

Slippery panels due to oil, narrow areas to grip, reliability and speed in the press are all factors to consider in designing your vacuum system of suction cups and vacuum ejectors. Using our products created especially for the Automotive industry, press shop sheet metals are moved across the press quickly and efficiently.

What Piab offers

- Tailor-made cups: unprecedented design for handling oily sheets; our suction cups are made to keep their grip.

- Efficiency: our suction cups and vacuum ejectors are made to match the speed of the press line

- Reliability: safe and sturdy to move heavy pieces at no cost to human safety

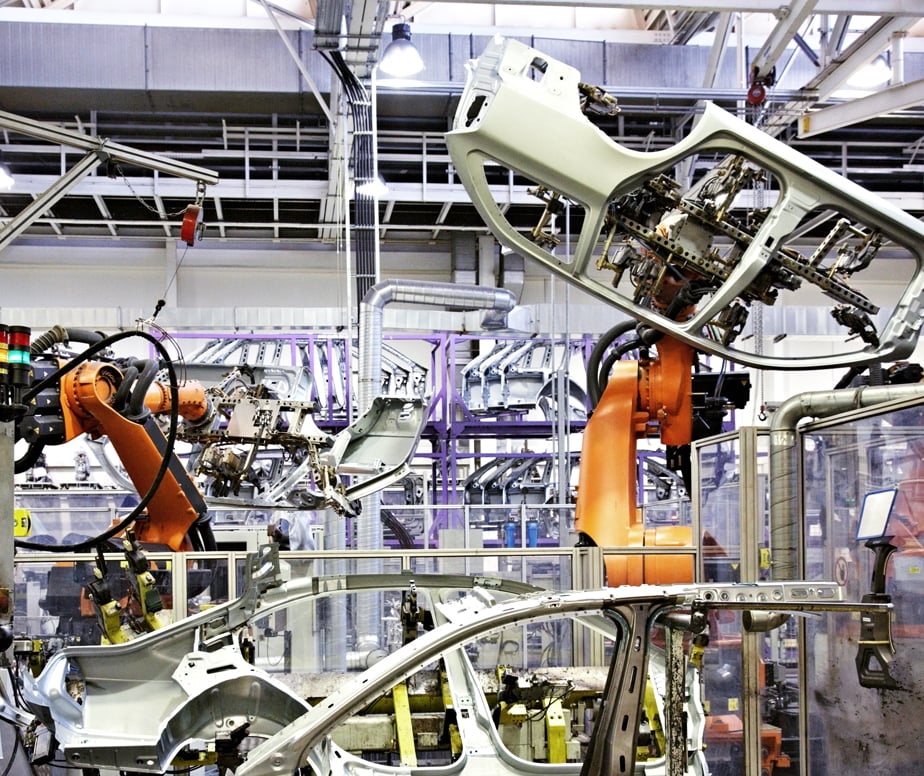

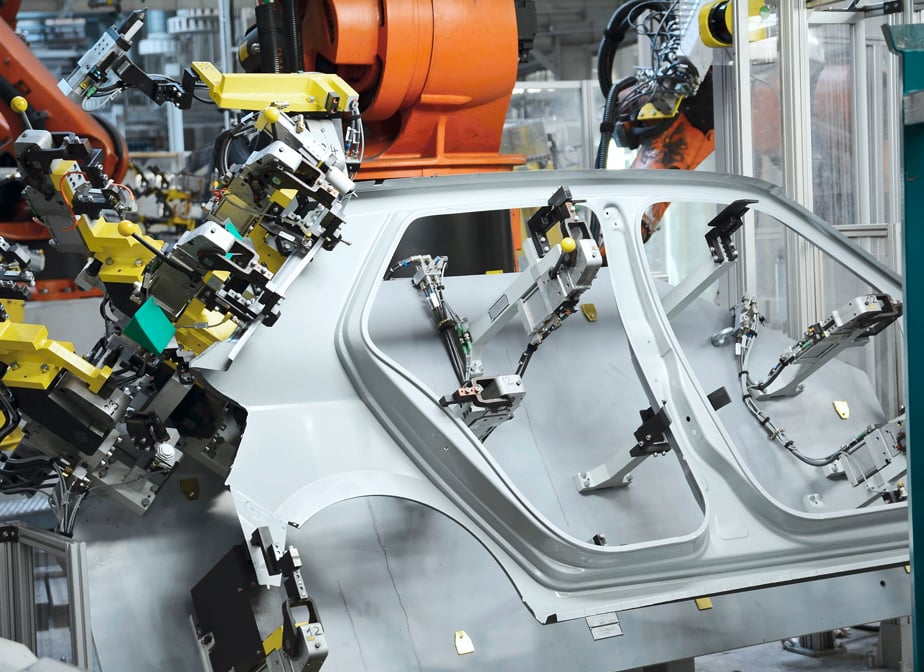

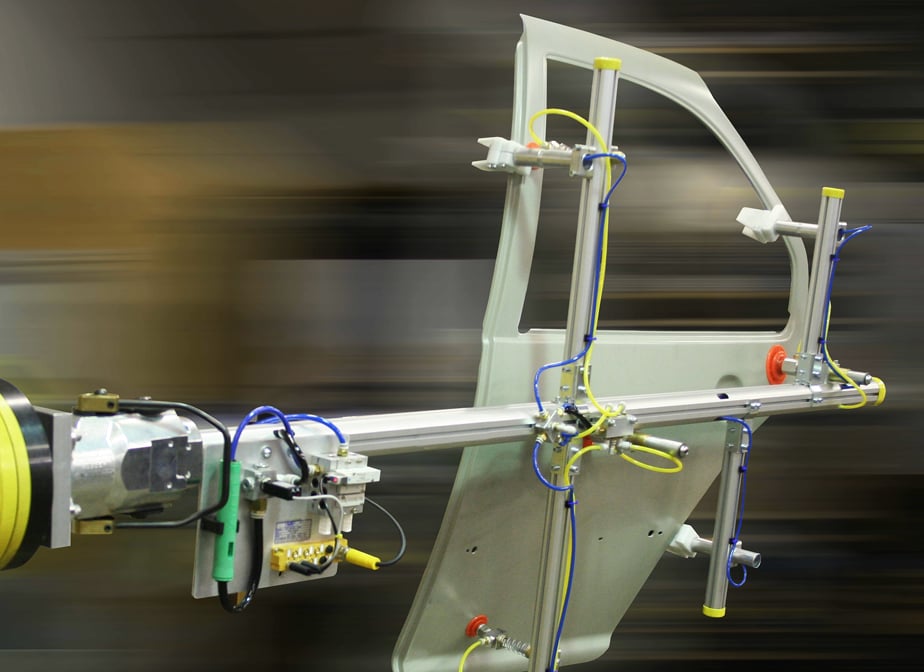

Body assembly

In the Automotive industry, body assembly speed and safety are the first priorities. The metal sheets are heavy and oily, requiring the need of our energy efficient vacuum gripping solutions and specially designed friction cups to help lift, grip, and move products along the assembly line. Our solutions are flexible during production and are robust and reliable, offering maximum safety in case of power failure.

What Piab offers

- Tailor-made cups: unprecedented design for handling oily sheets; our suction cups are made to keep their grip.

- Efficiency: our suction cups and vacuum ejectors are made to match the speed of the press line

- Reliability: safe and sturdy to move heavy pieces at no cost to human safety

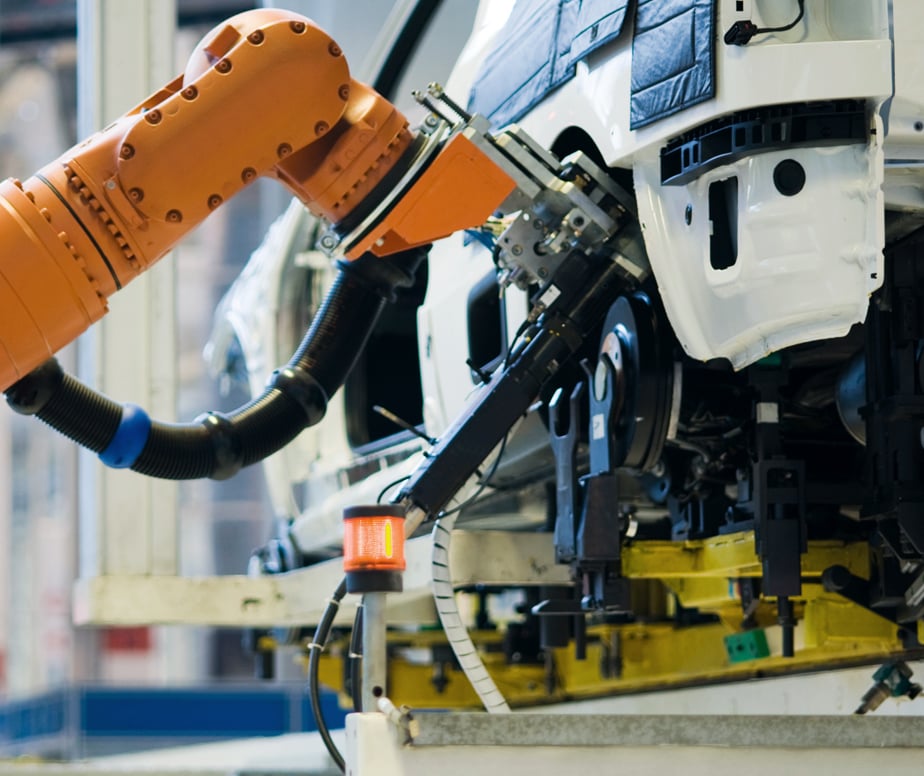

Final assembly

In the final assembly (after paint-shop), the vehicle is equipped with heavy exterior and interior parts such as bumpers, dashboards, tires, windscreens, and even brakes and AC systems. Our vacuum products together with robots help to lift these parts safely and efficiently. And thanks to our large selection of suction cups you will find the right grip without leaving any marks.

What Piab offers

- Mark free parts: our wide selection of suction cups guarantee mark free handling

- Efficiency: our suction cups and vacuum ejectors are made to optimize the speed of the assembly line

- Reliability: innovative vacuum systems and components secure handling delicate, heavy, and high value parts at no cost to human safety

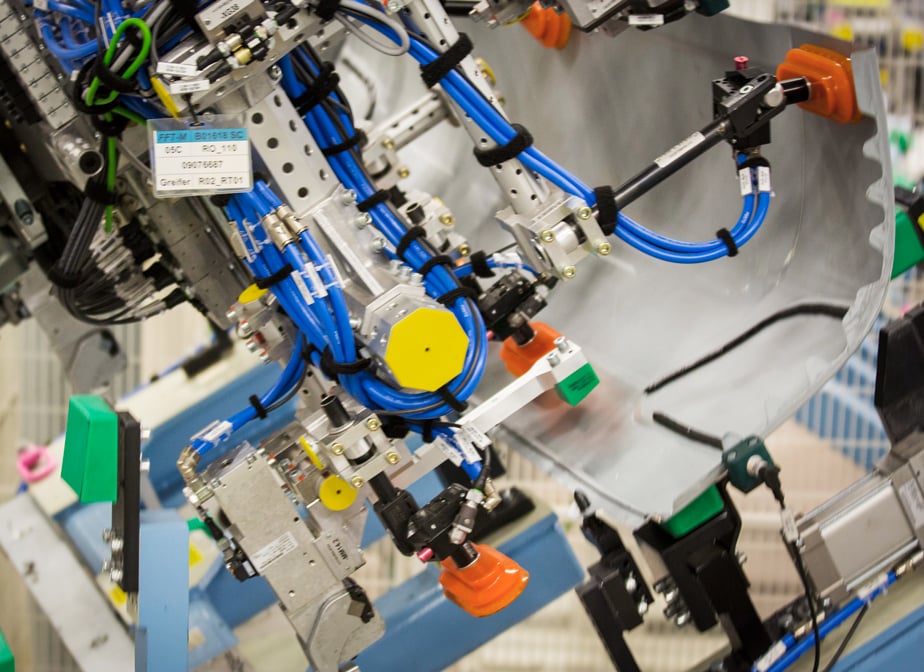

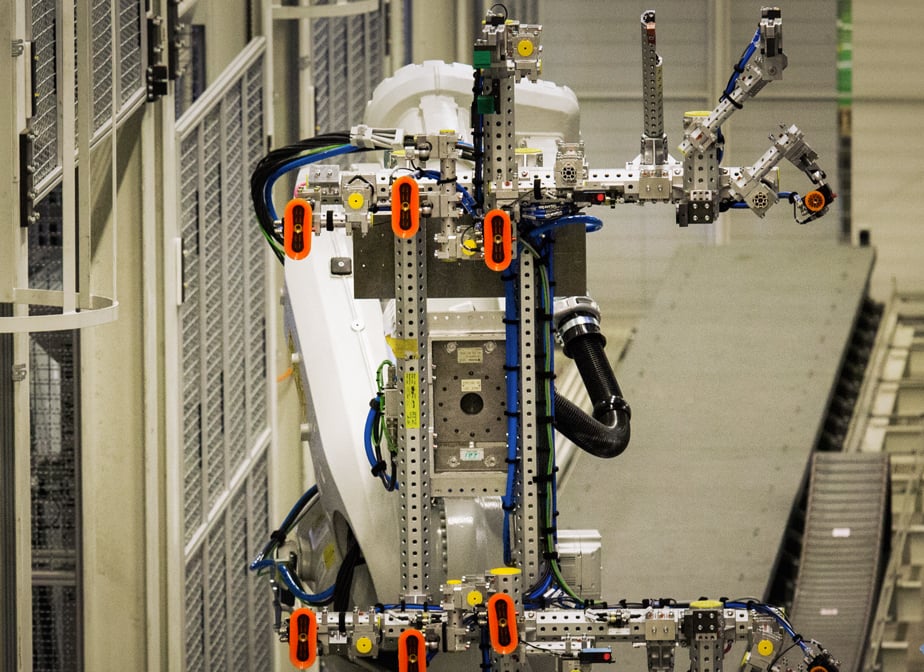

Plastic moulding shops

Automobiles consist of large amounts of plastic parts which require reliable handling both during de-moulding and part handling as well as during de-gating and cutting operations. Having a secure grip with both vacuum and mechanical gripping is essential to produce damage free, high quality plastic parts.

What Piab offers

- Quality: End of Arm tools, which cycle after cycle securely handles your automotive parts

- Enhanced production: innovative component systems, which allow for handling both simple and complex cuts

- Reliability: robust design of component and End of Arm tool systems

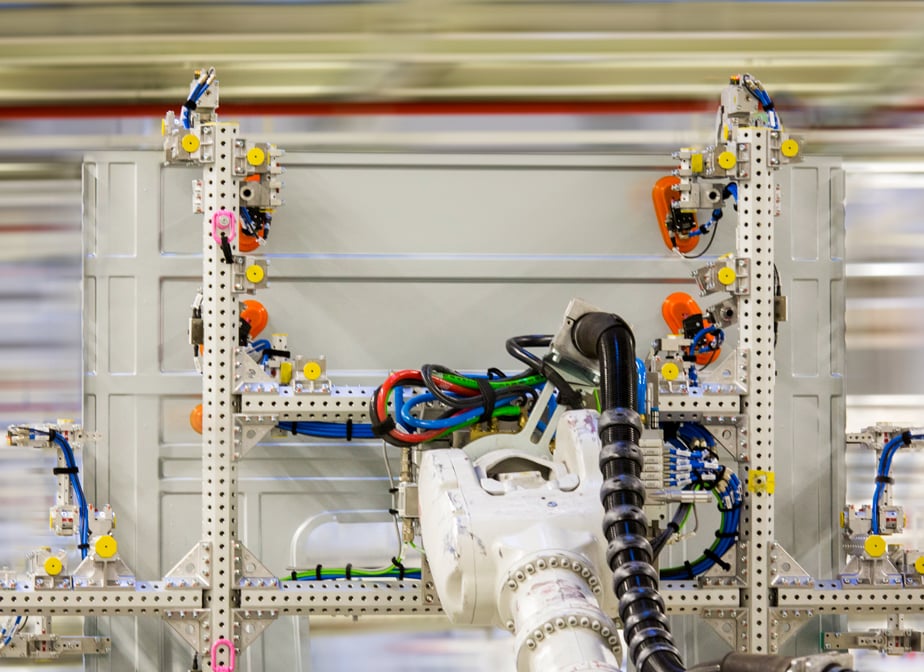

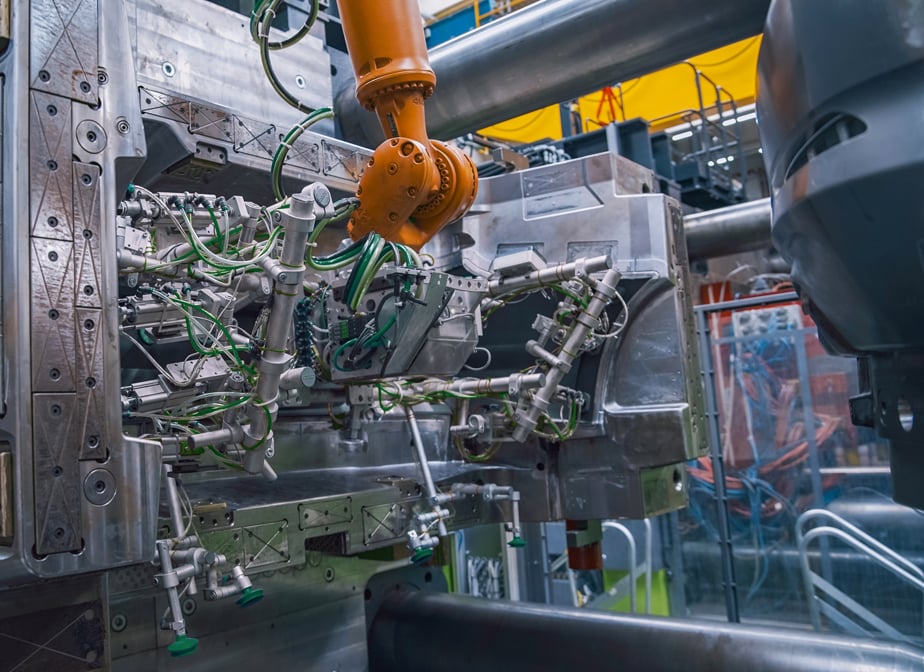

Tailor welded blanks

Prior to stamping car panels in the press shop, large, blank metal sheets are welded together to optimize the safety and structure of the vehicle. We help to load and unload these heavy metal sheets using our innovative vacuum gripping technology. Our suction cups guarantee carrying a metal sheet without creating dents and to release the sheets safely, which leads to faster cycle times and higher productivity.

What Piab offers

- Dent free: our suction cups are made to carry and release heavy sheets without creating dents

- Increased productivity: our vacuum systems and suction cups ensure faster cycle times

- Reliability: innovative vacuum systems and components secure handling delicate, heavy, and high value parts at no cost to human safety