Artikelnummer: 0207726

9 Varianter

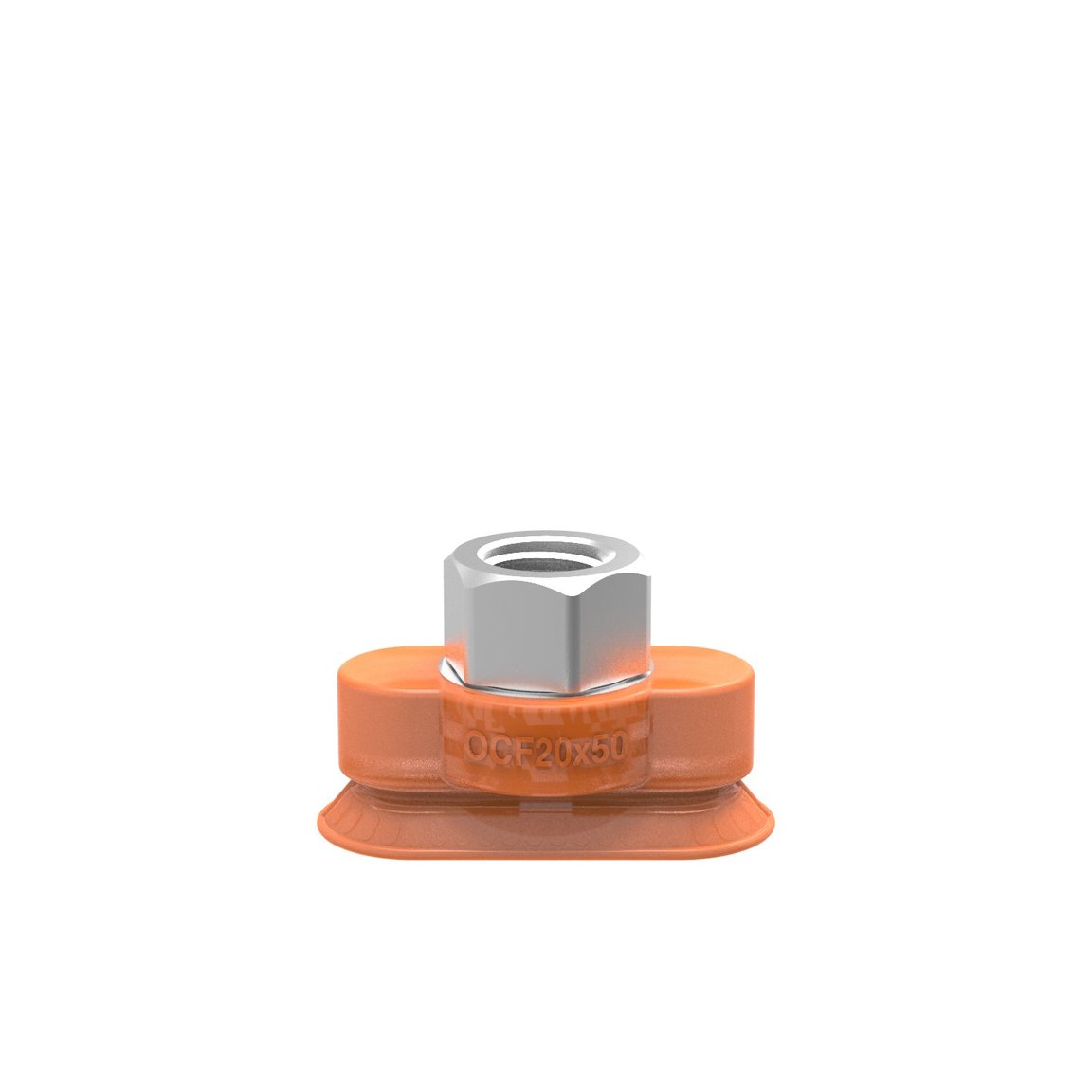

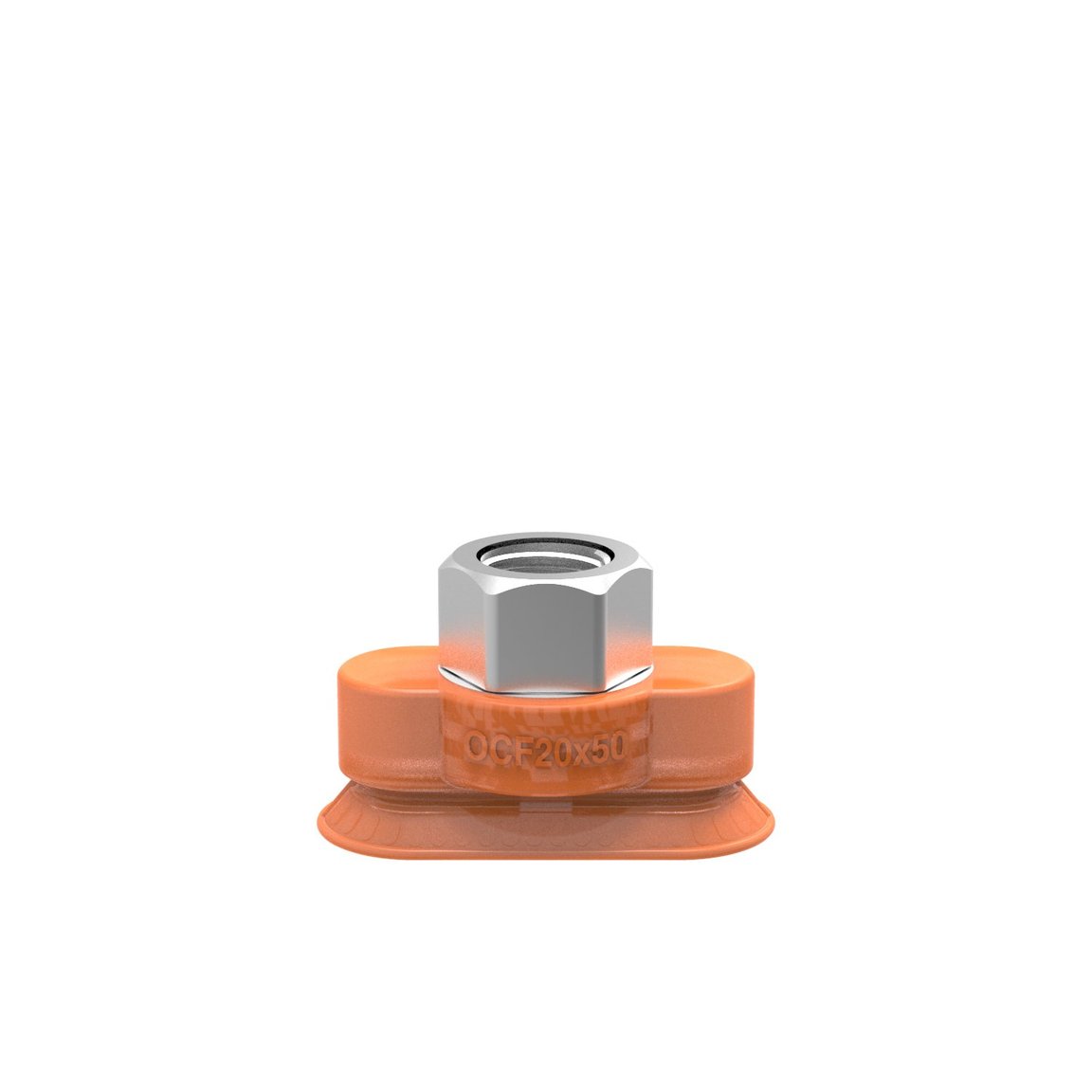

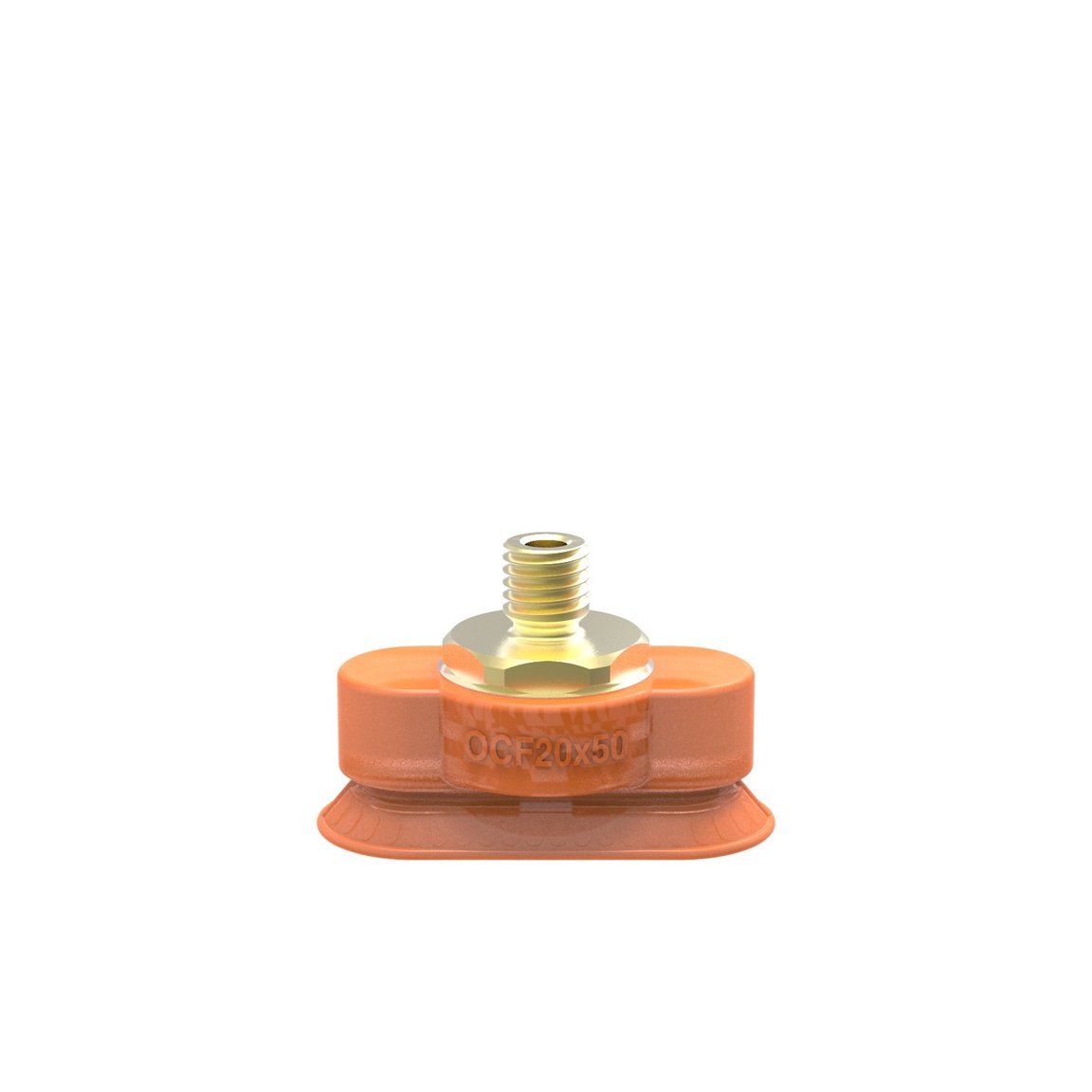

Suction cup OCF20×50 Polyurethane 60, T-slot with mesh filter

Logga in eller skapa ett konto för att komma åt allt vårt innehåll och alla funktioner!

Välj variant

0209497

0209497 0207727

0207727 0207728

0207728 0207726

0207726 0207730

0207730 0207731

0207731 0207732

0207732 0207729

0207729 0207618

0207618

Funktioner

- Special designed friction cups for oily surfaces, such as sheets in metal forming processes.

- Normal wear on friction cup will not affect the long term shear force performance.

- Best choice if > 0,1g/m2 press oil is used on the sheet.

- Thanks to the strong grip on oily surfaces, the suction cups can withstand high shear forces, typically 2–4 times more than corresponding conventional suction cups.

- The "OCF" design is suitable for oblong objects with slightly curved or flat surfaces.

- DURAFLEX® suction cups manufactured in a specially developed material that features the elasticity of rubber and wear resistance of polyurethane. The material does not leave any marks on the objects handled.