高精度な熱成形品のハンドリングを実現

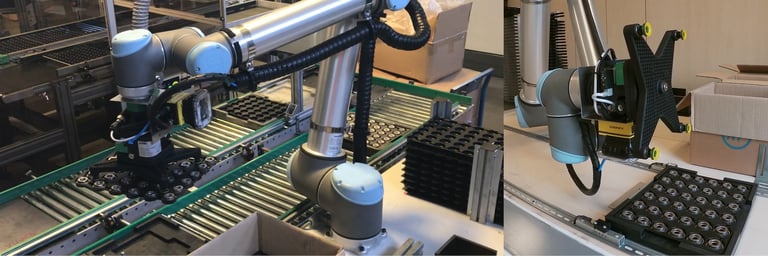

システムインテグレーターのUmbra Controlは、自動車業界向けのシールを製造するMeccanotecnica Umbraのラインにて、ピックアンドプレースを正確かつ効率的に処理するために、サクションカップを4個装着した特別仕様のPiab Kenos®KCSグリッパーを採用しました。

Umbra Controlは、Meccanotecnica Umbra SpAのアッセンブリラインに設置された協働ロボットにKenos® KCSグリッピングシステムを採用しました。このプロセスのオートメーション化以前は、オペレーターの手作業で行われていました。現在この作業は、Universal RobotのUR10協働ロボットが処理しています。ロボットはKCSグリッパーを使用して、シールリングを含む熱成形されたモールドとトレーをハンドリングします。 それぞれのキャビティにシールリングが配置された熱成形モールドは、コンベアベルト上のラインの端に到達し、フォトセルによって検出されます。

協働ロボットは、カメラでモールドをフレームに収め、キャビティ内全てのコンポーネントをチェックできるように配置されます。この段階で、UmbraControlによってUR10に統合されたビデオ分析システムが、シールリング固有のコードを読み取ります。その情報は、協働ロボットのオペレーターがチェックできるようにタッチスクリーンに表示されます。新しいオフライン音声コマンドシステムとともに、タッチスクリーンはシステム全体の制御インターフェイスとして機能します。

協働ロボットは、制御されたシールリング付きの熱成形モールドをピッキングし、ボックスに運びます。その後、下にある空のトレーをピッキングし、コンベアベルトの始点に置きます。最後に、協働ロボットはラインの先頭にあるラックから空の熱成形モールドをピッキングし、コンベアの始点にあるトレーに置きます。

協働ロボットは、それぞれ36個のシーリングリングを備えた12個の熱成形モールドで構成されるボックスを埋めるまでこのサイクルを繰り返し、次に中間層を挿入してボックスを完成させてから閉じます。このプロセスは、1個の熱成形モールドの積み込みに約100秒のサイクルタイムを要し、1箱仕上げるのに15〜20分掛かります。この工程で重要なのはスピードではなく精度です。Meccanotecnica Umbraの作業の許容誤差はゼロなのです。

「問題は、シールリングの付いた熱成形モールドとそれを運ぶトレーという2種類の表面に対する確かなグリッピングソリューションを見つけることでした」と、プロジェクトを指揮する、Umbra Controlソフトウェア研究開発マネージャーのGiorgio Passeri氏が語ります。「プラスチック製の熱成形モールドは、その形状を保証するほど曲げ剛性が高いとは言えません。これがグリッパーの選定に大きく影響しました。当初、手の指の動作をシミュレートするシステムとサクションカップを備えた工業用のエンドエフェクターの評価を行いました。これらは、熱成形モールドが外側に曲がってしまい、不採用となりました。そのため、カスタマイズしたグリッパーを開発する必要があり、Piabと共同でそれを行いました。

Kenos® KCSシステムを選択し、エンドエフェクター内のサクションカップの位置間隔が広がったことで、熱成形モールドを最も外側の部分で持ち上げることができるようになり、ワークの曲げを避けることができました。初めは、サクションカップを5個使用するソリューションから始めました。しかし、サクションカップ5個ではテストで効率的にグリッピングすることができず、熱可塑性材が曲がってしまいました。そこで、中央のサクションカップを取り外すことにしました。

エンドエフェクターの四隅にあるサクションカップの真空配管は、中央のサクションカップの配管よりも長いものでした。この長さの違いから、中心のカップが周囲のカップよりも早くグリッピングが始まり、その結果、熱成形材が変形し、効率的にグリッピングできなくなっていたのです。サクションカップを4個にすることで、この問題は解決しました。これはまた、熱成形モールドよりも表面が規則的で曲げ剛性が高いトレーにも最適であることが証明されました」と、GiorgioPasseri氏は説明を加えます。

「グリッパーの性能を支えているのは、Kenos®KCSグリッパーに内蔵されているPiabのCOAX®エジェクターです。ポンプの重要な機能の一つは、ワークのリリースを促進するブローオフ機能です。この機能がなければ、真空発生を停止した時にサクションカップがワークをしっかりとリリースすることができないでしょう。私達が選んだPiabのソリューションは、同社の技術者が提供してくれたコンサルティングサービスを考慮して、経済的に非常に競争力の高いソリューションだと感じました。Piabの認定販売代理店であるMategの協力もあり、最善の方法で私達をガイドしてくれました」とGeorgio Passeri氏は締めくくります。

PiabのKenos®真空グリッパーは、さまざまな産業アプリケーションでの搬送プロセスを簡略化するために開発されました。Kenos® KCSグリッパーは、協働ロボット用のモデルです。コンパクトなモジュール式の真空発生器で構成される、プラグアンドプレイシステムのグリッパーです。標準仕様では、多様なワークに適応できるフォームパッドが付いています。Umbra Controlの例のように、用途に合った仕様にカスタマイズすることも可能です。

Piabの真空発生技術COAXは、エネルギー消費量を最小限に抑えつつ、初期真空流量の高さにより安全で高速なグリッピングを実現します。ポンプユニットは、空気供給圧が低くなったり変動したりする時でも安定した性能を発揮します。