Piab piFLOW®p SMART CCO (Conveying Cycle Optimization)で粉体搬送を容易に

オペレーターのスキルに依存せず、エネルギーコストを抑え、より多くの搬送物を運ぶことができたら素晴らしいと思いませんか? Piab最新のプレミアムコンベアシリーズを是非ご覧ください。

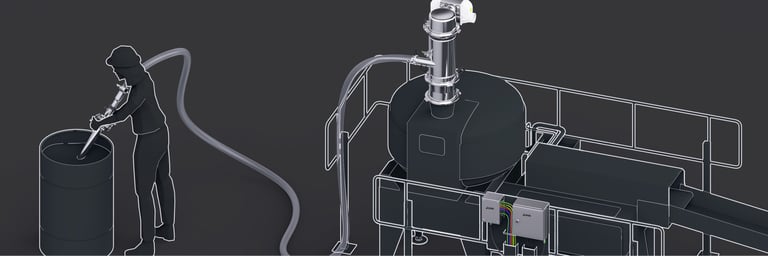

Piabの半自動バキュームコンベア piFLOW®p SMART CCO は、フレコンバッグやドラム缶からフィードノズルを使用して搬送物を吸引するアプリケーションに焦点を当てています。

包装機、ふるい機、破砕機、混合機などへの粉体供給を、より少ない搬送サイクルで済むように調整をします。piFLOW®p SMART CCOは、サイクルごとの搬送能力を最大限に引き上げ、搬送プロセスを最適化します。

搬送バッチ容量を最適化するための鍵

デュアルセンサーソリューション搭載により、piFLOW®p SMART CCOは各サイクルで最大限のバッチ容量を搬送します。オペレーターが設定するのは、搬送エアバルブの値だけです。その他全ての設定は、コンベアが自動的に調整します。

トップセンサーは、コンベアのコンテナ内の容量を測定し、最大レベルに到達すると、充填サイクルを停止します。ボトムセンサーは、コンテナが空になると、ボトムバルブを閉じ、直ちに搬送プロセスを再開します。

固有のシステム保護

piFLOW®p SMART CCOのトップセンサーは、材料の過充填対策としても機能します。材料がフィルターに到達する前に搬送サイクルを停止することで、フィルターが保護され、ダウンタイムとフィルター交換費用の削減に繋がります。

搬送サイクルの排出段階では、エアショックが働いてフィルターが掃除されます。この機能により、フィルターの製品寿命が長くなります。搬送物に応じて、エアショックの回数は1~5回で設定できます。同時に、エアチャネルによって、センサーの検知部も、搬送物の排出中に信号が解除されるまで、エアブローで掃除されます。

スクリューコンベアのように容易に使用できます

それほど技術のないオペレーターでも、スクリューコンベアを使うように容易かつ感覚的にpiFLOW®p SMART CCOを使用することが出来ます。piFLOW®p SMART CCOが自動的に吸引・排出時間を搬送物に合わせて調整するため、オペレーターが設定する必要があるのは搬送エアバルブの値だけです。そのため、オペレーターがパフォーマンス向上のための微調整に何サイクルも時間を費やす必要がありません。

吸引・排出時間を手動で自由に設定することも可能です。その場合、オペレーターは搬送物に合わせた設定を保存し、次回もその設定を使用することが出来ます。

全ての設定は、ユーザーフレンドリーなHMIを介して、電子制御ユニットで行います。

piFLOW®p SMART CCO その他の特徴:

- コンベアのコンテナ、および供給機器にある搬送物量を検知する外部レベルセンサー。

- フィードアダプターおよび搬送空気ユニットを追加することで、全自動調整システムへのアップグレードが可能

- 本体材質 ASTM316L(耐酸性ステンレススチール)

- FDA、EC No. 1935/2004およびEU No. 10/2011に準拠