Повышение производительности при формовке коробок в ветеринарии

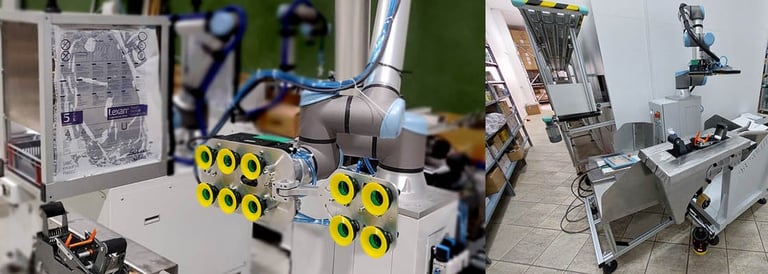

Используя присоски Piab B52XP и насос piCOMPACT23 SMART, компания Cob-Solution спроектировала и изготовила систему для подбора и открытия картонных коробок в Rao Farmaceutici, сицилийской ветеринарной аптеке, которая инвестирует в электронную коммерцию и осуществляет продажи по всей Европе.

Система Cob-Solution под названием CoBox Erector была установлена в отделе логистики на предприятии заказчика Partinico в провинции Палермо. Данное решение разработано для того, чтобы освободить оператора от повторяющейся работы по формовке и оклеиванию коробок лентой, позволяя ему посвятить себя задачам с более высокой добавленной стоимостью.

Цепочка процессов

Это полностью конфигурируемая система, которая предлагает возможность работы с коробками различных форматов, благодаря своей двухсекционной конструкции. Максимальная вместимость каждой секции составляет 40 штук при толщине коробки 5 мм. Система способна формировать и оклеивать лентой 4 коробки в минуту, забирая коробку в разобранном виде прямо со склада. Захват с решениями Piab используется на этапе формовки.

После формовки и оклейки лентой коробки помещаются на роликовый конвейер, расположенный над системой, и под действием силы тяжести опускаются на линию, где оператор заполняет их лекарствами, заказанными клиентами через Интернет. Они подаются на производственную линию с автоматического склада.

После заполнения коробки закрываются и заклеиваются системой Cob-Solution. Затем они проверяются оператором, автоматически маркируются и отправляются клиентам.

Установка Cob-Solution оснащена системой дистанционной помощи для сокращения количества вмешательств на месте и оптимизации времени и ресурсов.

Трудности с захватами

«Трудности заключались в разнице размеров форматов коробок, и эта проблема была решена благодаря поддержке технических специалистов Piab, которые позволили нам надежно и точно захватывать коробки даже самого большого и тяжелого формата для нашего клиента, — говорит Федерико Кароппо, генеральный директор Cob-Solution. —

Еще одной проблемой была пористость и жесткость картона. И здесь опыт технических специалистов Piab и Кристиана Мазетти из компании TMA, авторизованного дистрибьютора Piab, помог нам выбрать правильную технологию», — отметил Маттео Барбиери, технический директор Cob-Solution.

Сотрудничество и результаты

Федерико подчеркивает: «Компания Piab всегда первая в списке при выборе стандартизированных решений благодаря надежности, которую она может нам гарантировать. Для нас очень важно сотрудничать с поставщиком, который может определить размер и поставить полную систему вакуумного захвата, как в данном случае, избегая использования различных продуктов, что также усложнит заказчику получение запасных частей.

В заключении Маттео отметил: «Благодаря принятым автоматизированным решениям наш клиент добился увеличения производительности на 30 % и рассматривает возможность внедрения нашей системы на других производственных предприятиях. Большинство малых и средних компаний еще не до конца осознали, что может сделать для них коллаборативная технология, и мы помогаем компаниям достичь этого осознания».

Преимущества вакуумной технологии Piab

Сильфонные вакуумные присоски B-XP идеально подходят для неровных и пористых поверхностей, таких как картон. Они изготовлены из DURAFLEX®, материала, специально разработанного компанией Piab, который сочетает в себе эластичность резины и износостойкость полиуретана. К тому же, материал DURAFLEX® не оставляет следов.

Конфигурируемый вакуумный эжектор piCOMPACT®23 SMART на базе технологии COAX® разработан специально для роботизированных погрузочно-разгрузочных систем. Он включает в себя 2 электромагнитных клапана для создания вакуума и продувки, вакуумный переключатель и ряд сложных программных функций, которые снижают потребление сжатого воздуха и упрощают установку и программирование роботов благодаря своей чрезвычайной гибкости. Характеризуется улучшенной конструкцией для максимальной надежности, повышения объемной скорости потока и сокращения продолжительности цикла.

Технология создания вакуума COAX® компании Piab сводит к минимуму энергопотребление, обеспечивая при этом надежный и быстрый захват благодаря мощному начальному потоку.

Хотите узнать больше? Свяжитесь с нами!

О компании COB-Solution

Cob-Solution — это инновационный стартап, основанный в 2019 году и специализирующийся на коллаборативной робототехнике. Компания предлагает передовые решения по автоматизации с использованием новейших технологий с перспективой Индустрии 4.0, гарантируя более эффективные производственные процессы. Cob-Solution предоставляет клиентам специализированные навыки и ноу-хау, приобретенные в области промышленной автоматизации, проводит анализ производственных циклов и выявляет повторяющиеся задачи, которые можно легко автоматизировать. Все это приводит к повышению производительности. Машины Cob-Solution разрабатываются и производятся на основе конкретных требований, с использованием наиболее подходящего кобота для конкретной области применения. Гибкость и безопасность гарантированы по доступным ценам для всех компаний, желающих получить максимальную доходность по инвестициям.